Chia sẻ kinh nghiệm

SpectraX 55 Coating Thickness Gauge: Accurate and Fast

The SpectraX 55 Coating Thickness Gauge is an advanced device designed to measure the thickness of metallic coatings accurately, helping businesses in industries such as electronics, machinery, jewelry, and component manufacturing to quickly and efficiently check product quality. With modern X-ray technology and exceptional accuracy, the SpectraX 55 not only enhances production processes but also ensures products meet environmental safety and quality standards. In this article, DC Technologies will explore the outstanding features and practical applications of the SpectraX 55 Coating Thickness Gauge.

1. SpectraX 55 Coating Thickness Gauge

The SpectraX 55 Coating Thickness Gauge is a modern device that uses X-ray (X-ray) technology to quickly and accurately measure the thickness of metal coatings. Designed to measure various types of metallic coatings, the SpectraX 55 provides an effective measurement solution for businesses to inspect and control coating quality. With advanced technology and high accuracy, the SpectraX 55 is an indispensable tool in industries that require metal coating quality checks.

Key Specifications

Coating Thickness Measurement Accuracy: 0.001μm

Element Analysis Range: From Sulfur (S) to Uranium (U)

Measurement Time: 10 - 30 seconds

X-ray Source: 50kV/1mA, Mo/W target

Detector System: SDD, Resolution 125±5eV

Multi Collimators: 0.1 - 4.0 mm, automatic switching

Automatic Filters: 6 types

X-ray Beam Angle: 90°, top-down projection

Surveillance Camera: 2MP CCD, assists with precise alignment

XYZ Movement: 80 × 80 × 90 mm

Weight: 85kg

2. Key Features of the SpectraX 55 Coating Thickness Gauge

2.1 Advanced Technology - Intelligent Analysis Software

The SpectraX 55 is equipped with a high-end SDD (Silicon Drift Detector) detector system, X-ray technology, and a 2MP CCD camera, allowing for precise analysis of the metal composition in coatings. This allows users to accurately identify the alloy composition of the coating, ensuring that products meet technical and quality standards.

The intelligent analysis software with an easy-to-use interface allows users to generate reports in PDF or EXCEL formats without the need for a standard sample during analysis.

2.2 High Accuracy and Speed

One of the key strengths of the SpectraX 55 Coating Thickness Gauge is its exceptional accuracy. With the ability to measure thickness with an accuracy of 0.001μm, the SpectraX 55 helps businesses ensure that coatings meet quality standards, thereby enhancing the durability and aesthetics of the products.

With measurement times ranging from 10 to 30 seconds, the SpectraX 55 helps save inspection time without compromising accuracy. This is crucial in industrial environments where time is an essential factor in maintaining workflow efficiency.

2.3 Versatile Coating Thickness Analysis

The SpectraX 55 can measure not only the thickness of a single coating but also multiple layers of coatings, up to 4 layers of metal coatings and 1 base layer. This is particularly useful for inspecting products with complex coatings, such as printed circuit boards (PCBs) or mechanical components.

Additionally, the SpectraX 55 can measure and analyze a wide range of metallic coatings, including gold (Au), silver (Ag), palladium (Pd), platinum (Pt), rhodium (Rh), copper (Cu), nickel (Ni), zinc (Zn), chromium (Cr), and more. This makes the device suitable for a variety of industries.

3. Applications of the SpectraX 55 Coating Thickness Gauge

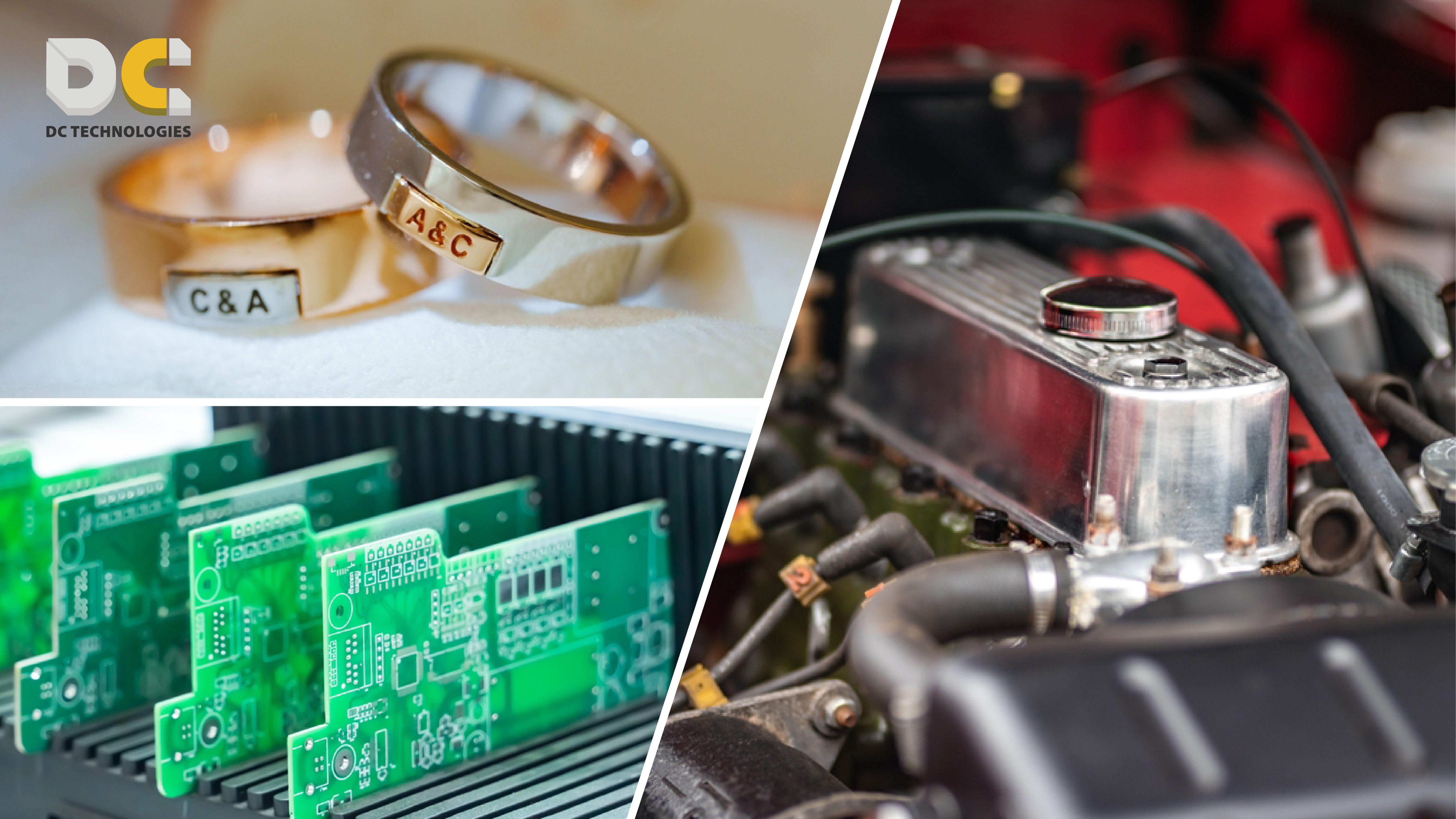

The SpectraX 55 is an ideal solution for various industries. Below are some common applications for this coating thickness gauge:

3.1 Electronics and PCB Manufacturing

In the electronics industry, checking the coating thickness on printed circuit boards (PCBs) is crucial to ensure electrical conductivity and the durability of components. The SpectraX 55 can measure the coating thickness on PCBs and electronic components such as pins, microchips, and connectors, helping to ensure product quality and operational performance.

3.2 Mechanical Engineering and Component Manufacturing

In the mechanical engineering industry, inspecting the coating thickness on automotive parts, industrial machinery, and household appliances is necessary. The SpectraX 55 ensures that the metal coating on these components meets quality, durability, and aesthetic requirements before they are put into use.

3.3 Jewelry and Precious Metal Manufacturing

The SpectraX 55 Coating Thickness Gauge is used to measure the coating thickness of gold, silver, rhodium, platinum, and other precious metals on jewelry products. Additionally, it can analyze alloy compositions, helping to inspect the quality of jewelry items, ensuring their aesthetic value and market worth.

3.4 Compliance with RoHS/WEEE/ELV Standards

With its precise metal composition analysis capabilities, the SpectraX 55 also helps check for hazardous substances such as lead (Pb), mercury (Hg), cadmium (Cd), bromine (Br), arsenic (As), antimony (Sb), and sulfur (S) in electronic products and consumer goods. This ensures that businesses meet international environmental standards such as RoHS, WEEE, and ELV.

4. DC Technologies - Supplier of SpectraX 55 XRF Coating Thickness Gauge

DC Technologies offers professional after-sales services for the SpectraX 55 Coating Thickness Gauge. When purchasing the product, customers will receive free installation at their facility and device usage training. Additionally, the device comes with a free warranty, providing peace of mind regarding its quality and long-term performance.

DC's technical support team commits to responding quickly within 2 - 48 hours to resolve any issues promptly without interrupting operations. Moreover, customers will receive lifetime free software upgrades to ensure that the device stays up-to-date with the latest features and optimal performance.

With these professional after-sales services, DC ensures ongoing support, helping businesses effectively and sustainably use the SpectraX 55 Coating Thickness Gauge.

5. Conclusion

The SpectraX 55 Coating Thickness Gauge is an advanced and efficient device for businesses in industries such as electronics, mechanical engineering, jewelry, and component manufacturing. With high accuracy, fast measurement times, and advanced technology, the SpectraX 55 optimizes quality control processes, ensuring that products meet technical and environmental safety standards. If you are looking for a professional coating thickness measurement solution, the SpectraX 55 is definitely a worthy investment! Contact DC Technologies now for detailed consultation and technical support!