Chia sẻ kinh nghiệm

The Best Quality Jewelry Polishing Burs Available Today – Super Q

In the jewelry industry, every small processing operation demands high precision and absolute delicacy. To achieve this, a jeweler not only needs skilled hands but also must use high-quality specialized tools. Among the indispensable tools in the jewelry making process are polishing burs.

Currently, among the popular polishing bur lines on the market, Super Q is highly regarded by jewelers for its sharpness, superior durability, diverse designs, and optimal efficiency in every operation. The following article by DC New Technology will help you better understand why Super Q polishing burs are the ideal choice for modern jewelry stores and workshops.

1. Super Q Polishing Burs – A Reliable Brand in the Jewelry Industry

Although small, polishing burs play an extremely important role in shaping, smoothing, and surface treatment of metals and gemstones. The difference between a perfect product and a flawed one sometimes lies solely in choosing the right type of polishing bur.

Super Q is a high-end polishing bur line manufactured according to German standard technology, notable for its ultra-durable stainless carbon steel material. This is a specialized brand serving the jewelry making industry, with a focus on quality and precision as top priorities.

Super Q products are currently widely distributed in major markets such as Vietnam, Thailand, India, and China – where the jewelry industry is strongly developed and has stringent requirements for processing equipment. Super Q has not only won over professional jewelers but is also highly appreciated by large-scale jewelry manufacturing facilities.

2. Outstanding Advantages of Super Q Polishing Burs

2.1 Stainless Carbon Steel Material – Superior Durability

Super Q polishing burs are made from stainless carbon steel, which has high hardness, good wear resistance, and does not rust during long-term use. As a result, the product can maintain its sharpness for a long time, minimizing rapid wear or breakage like common types.

This material also ensures safety when working with precious metals such as gold, silver, and platinum, helping to prevent scratching, burning, or loss of detail on the surface.

2.2 Precise Machining – Stable Operation

Each Super Q polishing bur is manufactured with modern technology, ensuring high concentricity and precision. Thanks to its balanced design, when operating with polishing machines or flexible shafts, the bur runs stably with minimal vibration, helping the jeweler maintain better control and avoid damaging the workpiece.

2.3 High Sharpness – Reduced Processing Time

One of the factors that jewelers love about Super Q is its exceptional sharpness. The polishing bur can rapidly remove material and create precise shapes, helping to save time in each stage, from roughing to finishing the product.

3. Diverse Product Range – Comprehensive Service for Jewelers

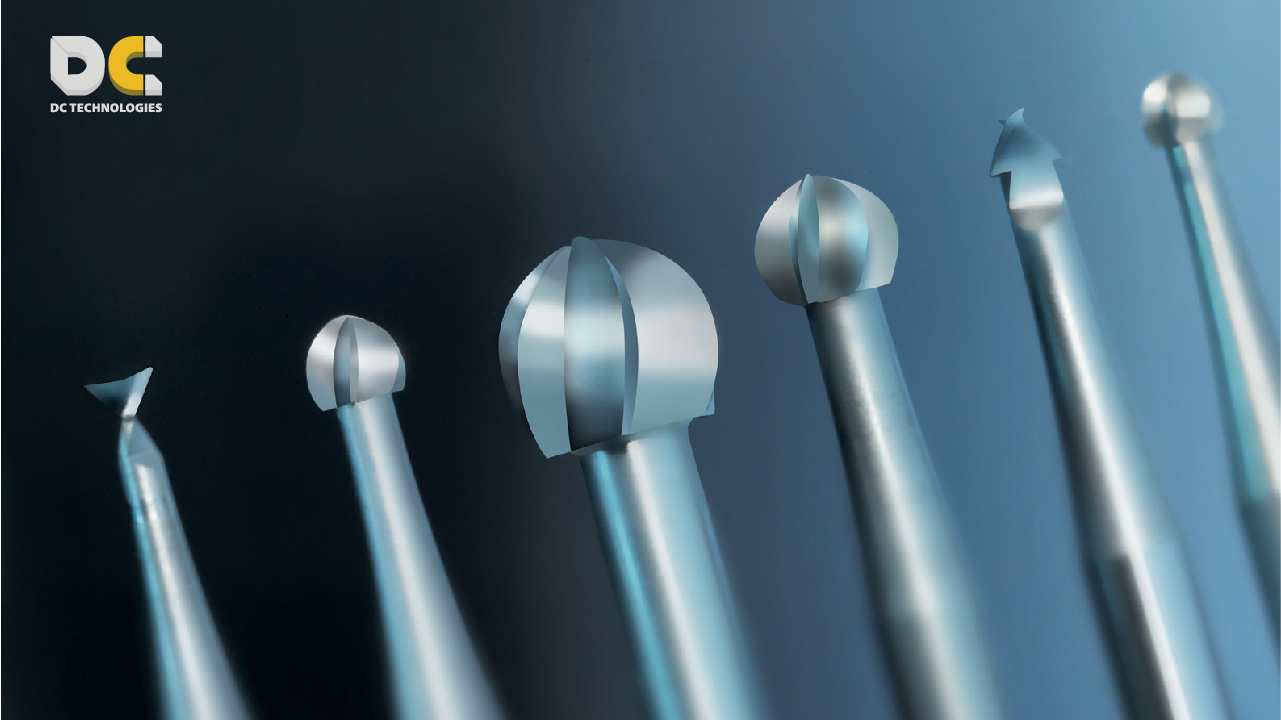

Super Q offers a full range of specialized polishing burs, suitable for each specific purpose in the jewelry making process:

- 45-degree Bevel Burs: Commonly used for chamfering edges and preliminary processing of the inner and outer surfaces of products. The beveled design allows for quick operation without causing edge breakage.

- 90-degree Bevel Burs: Used for right angles and rounding groove edges, suitable when sharp detail processing is required.

- Bud Burs: Ideal for polishing and finishing products with curved surfaces or small, confined areas.

- Flower Burs: Particularly effective when processing complex details such as patterns, deep grooves, and narrow corners.

- Cylinder Burs, Ball Burs, Needle Burs, Round-End Pointed Burs: Used for intricate pattern carving, creating small grooves, and precise hole drilling.

Super Q's provision of a diverse range of burs makes it easy for jewelers to choose the right tool for each step, thereby increasing work efficiency and minimizing errors.

4. Comparison of Super Q with Common Polishing Bur Lines

5. Practical Applications – Optimal Solutions for Jewelry Stores and Workshops

Using Super Q polishing burs not only helps improve work productivity but also enhances the quality of finished products, thanks to:

- Fast processing with less need for rework

- Reduced scratching and burning of workpieces

- Optimized production processes with lower operating costs

- Helping new jewelers easily control operations and reduce the risk of damaging products

- Super Q is suitable for both handmade and industrial jewelry production, especially ideal for jewelry stores upgrading to more professional workflows.

6. Where to Buy Genuine Super Q Polishing Burs?

To ensure the purchase of genuine Super Q polishing burs with German standard quality, customers should choose reputable distributors. DC New Technology is currently one of the main distributors of the Super Q polishing bur line in Vietnam, specializing in providing equipment and tools for the jewelry industry.

When purchasing from DC New Technology, you will receive:

- Consultation to choose the right type of bur for each operation

- Guarantee of genuine products and technical warranty

- Competitive prices and good deals for workshops and dealers

- Nationwide delivery and prompt exchange/return support

In the jewelry making process, investing in quality tools not only helps increase productivity but also creates higher-value products. Super Q polishing burs, with their high-quality materials, precise design, and diverse range of models, are powerful assistants that help jewelers work faster, more accurately, and more efficiently.

If you are looking for a reliable, durable, sharp, and cost-effective polishing bur line, Super Q is the choice you should not overlook. Contact DC New Technology immediately for detailed consultation and special offers for jewelers, processing workshops, and jewelry stores nationwide.