Chia sẻ kinh nghiệm

SpectraX XRF Gold Analyzer – Accurate Differentiation of W and Re

As gold prices continuously set new records and fraudulent practices become increasingly sophisticated through the mixing of elements such as Wolfram (W), Rhenium (Re), Germanium (Ge), Ruthenium (Ru), Osmium (Os), and Iridium (Ir), the demand for accurate gold testing has become more urgent than ever.

To address this challenge, DC New Technology Joint Stock Company has introduced the SpectraX Gold Analyzer Series, which applies advanced XRF (X-ray Fluorescence) technology to quickly detect impurities, protect consumers, enhance transparency, and strengthen the reputation of businesses in the gold and jewelry industry.

I. Gold Market Context and the Need for Modern Analysis

1. Rising Gold Prices and Resource Scarcity

In recent years, gold prices have continuously reached record highs due to growing demand for investment, reserves, and industrial production. Gold is not only considered a safe-haven asset but also an essential material in high-tech industries.

However, the amount of naturally mined gold is increasingly scarce while demand keeps growing, creating significant pressure on both the jewelry and industrial sectors.

2. The Role of Gold in High-Tech Industries

Gold is used in electronics, aerospace, medicine, and defense industries because of its superior electrical and thermal conductivity and strong resistance to oxidation.

Particularly in electronic microcircuits, the thin layer of gold plating plays a decisive role in durability and performance. Therefore, gold has become an irreplaceable material in many high-technology applications.

3. The Need for Gold Recovery from Scrap

Due to the scarcity of raw materials, recycling and recovering gold from electronic waste, industrial components, or old jewelry is increasingly prioritized. However, recovered gold often contains impurities, making purity verification a major challenge for businesses.

II. Challenges in Verifying Gold Purity

Since 2010, the Vietnamese gold market has faced the problem of contamination by metals such as Ru, Os, and Ir. These are hard alloys that do not melt when using gas furnaces or conventional gold-melting equipment, and the alloys of these metals are even heavier than gold itself.

At one time, they could deceive both traditional XRF spectrometers and density measurement scales commonly used in jewelry stores.

Today, the issue of impurities mixed into raw gold has intensified once again, with the appearance of other metals that are even more difficult to detect, such as:

1. Fake Gold Containing Wolfram (W)

Wolfram (W), or tungsten, has a density very close to gold (Au), and therefore is often used to make counterfeit gold or alloy mixtures to deceive consumers.

With traditional verification methods, it is extremely difficult to detect gold containing Wolfram, causing significant losses to both businesses and customers.

2. Risks from Rhenium (Re) and Germanium (Ge)

In addition to Wolfram, elements such as Rhenium (Re) and Germanium (Ge) may also appear in gold—particularly from industrial scrap or certain mining sources.

Although less common, the presence of Re and Ge reduces the true value of gold and directly affects the reputation of businesses during transactions.

3. Limitations of Conventional Analytical Devices

Most gold-testing instruments currently available on the market can only measure the content of Au, Ag, Pt, and several basic metals.

Their ability to detect and distinguish rare impurities such as W, Re, and Ge remains very limited, exposing businesses to significant risk.

III. Modern XRF Technology for Gold Analysis

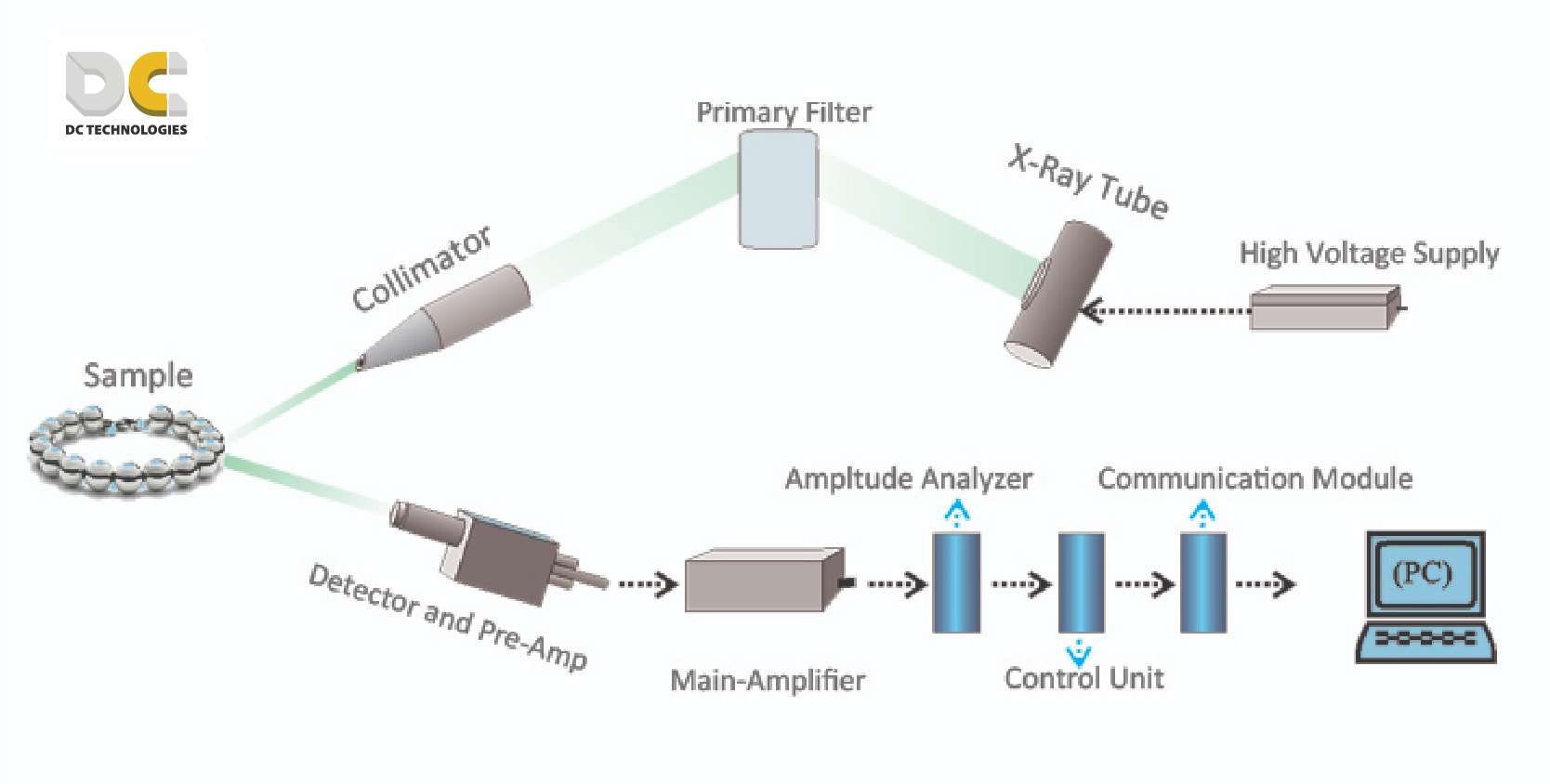

1. Principle of XRF Operation

X-ray Fluorescence (XRF) technology is one of the most advanced and widely used methods for material analysis today.

Its principle is based on directing a high-energy X-ray beam at the sample. When the atoms in the sample absorb this energy, inner-shell electrons are ejected, causing a rearrangement of remaining electrons and the emission of characteristic X-ray fluorescence unique to each element.

The XRF device then records these signals, generates a fluorescence spectrum, and analyzes it to determine the elemental composition and concentration.

2. Outstanding Advantages of XRF Technology

XRF technology is increasingly becoming the preferred choice for gold analysis and verification due to its notable advantages:

Ultra-fast analysis: Each measurement can be completed in just a few seconds—ideal for jewelry shops, goldsmiths, and production lines requiring speed.

High accuracy: The analysis results have an error margin as low as 0.01%, ensuring precise data for transactions, quality control, and research.

Multi-element analysis capability: In addition to gold (Au), the SpectraX analyzer identifies silver (Ag), platinum (Pt), and many other precious and base metals.

It is particularly effective in detecting impurities such as Wolfram (W), Rhenium (Re), Germanium (Ge), Ru, Os, and Ir—elements that are difficult to distinguish using conventional methods or typical XRF gold testers.Non-destructive testing: SpectraX does not require cutting, grinding, or dissolving the sample, preserving its integrity—an especially important feature for jewelry, components, or high-value samples.

Wide applicability: From jewelry, mining, metallurgy, electronics, and high-tech manufacturing to industrial inspection, SpectraX demonstrates exceptional value across industries.

3. Application of SpectraX in Gold Analysis

In the field of jewelry and precious metal recycling, SpectraX has become an indispensable tool.

Typical applications include:

Accurate gold content determination: Assisting businesses, laboratories, and jewelry stores in verifying gold purity, ensuring transparency in transactions.

Detection of fake and plated gold: SpectraX can quickly identify gold containing Wolfram or alloys with similar specific gravity—something traditional weighing methods cannot detect.

Evaluation in gold recycling from scrap: The recycling industry increasingly focuses on recovering gold from electronic components, circuit boards, or industrial waste. SpectraX allows for rapid and precise quantification to optimize the recycling process.

Distinguishing precious metals from rare impurities: Elements such as Re, Ge, and certain compounds can distort the true value of gold. SpectraX helps eliminate this risk, enhancing credibility for jewelry businesses.

IV. Advanced Gold Analysis Solution – The SpectraX Series

1. Next-Generation Gold Testing Technology – SpectraX

In the context of increasingly sophisticated gold fraud and the growing need for quality inspection, DC New Technology Joint Stock Company has pioneered the introduction of the SpectraX Series, one of the most advanced XRF devices available today.

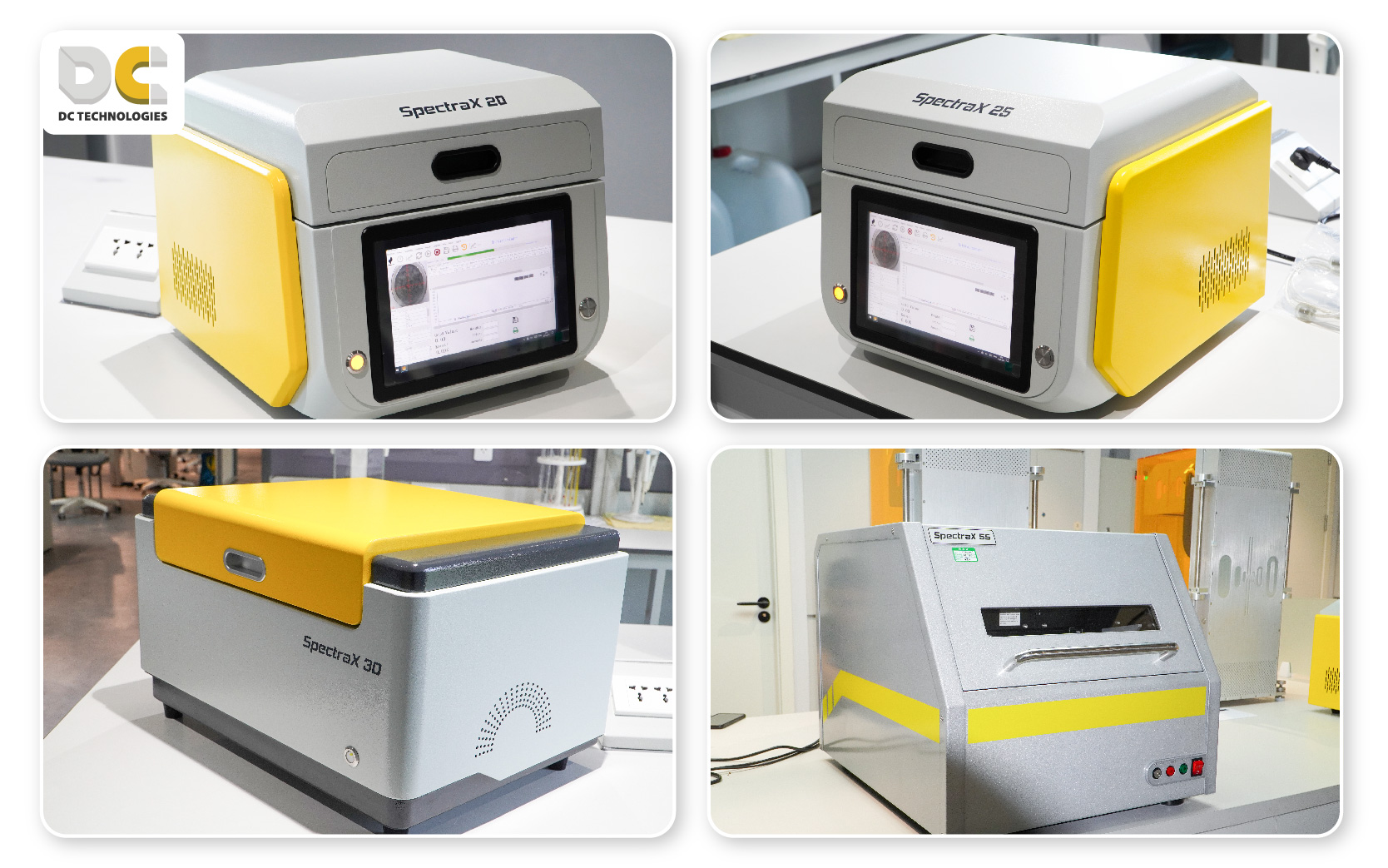

Key models such as SpectraX 20 and SpectraX 25 are specifically designed for gold karat measurement, precious metal verification, and impurity detection in alloy samples.

SpectraX 20: Compact and user-friendly, ideal for jewelry shops, enabling on-the-spot gold testing.

SpectraX 25: Equipped with a modern Silicon Drift Detector (SDD) for rapid analysis and high spectral resolution—particularly useful for manufacturing enterprises or gold testing centers.

Beyond measuring gold (Au), silver (Ag), and platinum (Pt) content, SpectraX enables simultaneous multi-element analysis, helping businesses save time and enhance testing efficiency.

2. Smart and Compact Design

One of the major advantages of the SpectraX line lies in its compact, modern design and optimized user experience.

Whereas previous XRF analyzers were often bulky and suitable only for large laboratories, SpectraX breaks through these limitations.

The device is engineered with a minimalist design, easy to transport, and can be operated directly on site.

This provides maximum flexibility for users—from jewelry shops, retail gold businesses, and goldsmith workshops to enterprises involved in gold extraction or recycling from industrial scrap.

Moreover, its intuitive interface, high-resolution display, and smart control software make SpectraX easy to operate, even for first-time users.

As a result, companies can reduce laboratory investment costs, shorten testing time, and significantly increase productivity in daily operations.

3. Exceptional Capability in Differentiating W, Re, and Ge

A key feature distinguishing SpectraX from many other XRF analyzers on the market is its ability to detect and differentiate rare impurities such as Wolfram (W), Rhenium (Re), and Germanium (Ge)—elements notoriously difficult to identify.

Wolfram (W): With a specific gravity very close to that of gold (Au), it is often used by counterfeiters to create imitation gold that traditional weighing methods fail to detect.

Rhenium (Re) and Germanium (Ge): Although less common, these elements may appear in gold extracted from ores or recovered from high-tech industrial scrap. Their presence can significantly alter the true value of gold and affect a company’s credibility.

By integrating an advanced SDD detector with high spectral resolution, SpectraX can detect and quantify these elements at the ppm (parts-per-million) level—a capability that most conventional XRF devices have yet to achieve.

This makes SpectraX an ideal solution for protecting businesses against counterfeit gold and reinforcing customer trust in transactions.

V. Benefits of Using the SpectraX Analyzer

1. For Jewelry Businesses

In the jewelry industry—where every transaction carries high value—ensuring the quality and purity of gold is crucial. SpectraX provides comprehensive benefits:

Ensures gold standards before transactions: Jewelry shops and manufacturers can precisely determine karat levels (e.g., 18K, 24K) within seconds.

Avoids risks from adulterated gold: With its advanced SDD detector, SpectraX accurately detects Wolfram (W), Rhenium (Re), and Germanium (Ge) even at trace concentrations.

Enhances brand credibility: When customers witness the testing process with a modern analytical device, their trust in product quality increases—helping jewelry businesses build a sustainable reputation and stand out in a competitive market.

Reduces testing costs: Instead of sending samples to external laboratories—which is both time-consuming and costly—businesses can perform on-site analyses, shortening production and transaction processes.

2. For High-Tech Equipment Manufacturers

In industries such as electronics, biomedical devices, and aerospace, gold and other precious metals are used with extremely high purity requirements to ensure conductivity, corrosion resistance, and stability. SpectraX offers tangible advantages:

Quality control of raw materials: Manufacturers can quickly analyze and screen incoming materials, ensuring only gold meeting standards is used in production.

Ensures purity in microcircuits and components: With analysis sensitivity down to the ppm level, SpectraX helps maintain product reliability and long-term performance.

Optimizes costs and conserves resources: Enables efficient use of precious materials, reducing waste and ensuring gold is used appropriately for technical requirements.

3. For Consumers

End users ultimately benefit most from the adoption of SpectraX analysis devices in the market:

Protection against counterfeit gold purchases

Accurate valuation in investments and transactions

Greater transparency and peace of mind in the gold market

Thus, SpectraX is not merely a precious-metal analyzer—it is a comprehensive solution ecosystem that benefits businesses, manufacturers, and consumers alike.

From ensuring transaction integrity and controlling raw materials in high-tech manufacturing to safeguarding customer rights, SpectraX plays a central role in building a transparent, modern, and sustainable gold industry.

VI. DC New Technology – Vietnam’s Leading XRF Distributor

1. Over 25 Years of Industry Experience

With more than 25 years of development, DC Technologies has established itself as a pioneer in transferring modern analytical technology to Vietnam’s jewelry and industrial sectors.

Beyond being a distributor, the company serves as a strategic partner to thousands of businesses, jewelry stores, and manufacturing facilities—helping them strengthen analytical capabilities, minimize risks, and enhance credibility in the marketplace.

2. Commitment to Genuine Products and Professional Service

DC Technologies is the official distributor of the SpectraX XRF analyzer series in Vietnam.

All products come with authentic certificates of origin and quality, ensuring customers can use them with complete confidence.

In addition to providing equipment, the company delivers comprehensive services, including:

On-site training for user operation

Official manufacturer warranty with lifetime technical support

Free software updates and periodic technology upgrades to maintain optimal device performance

Through its professionalism, DC Technologies provides customers not just with a product but with a complete solution, optimized for gold and precious-metal testing operations.

VII. Conclusion

As gold becomes scarcer and more valuable, verifying its purity is more critical than ever.

The emergence of counterfeit gold containing Wolfram (W), Rhenium (Re), and Germanium (Ge) demands analytical solutions that are modern, precise, and reliable.

The SpectraX XRF Analyzer from DC Technologies is such an advanced tool—helping businesses protect their reputation and enhance operational efficiency.

With fast analysis speed, high accuracy, and superior capability in identifying rare impurities, SpectraX has become the top choice for companies in Vietnam’s gold and jewelry industries.

In addition, DC Technologies offers a “Trade-in & Upgrade Program” with discounts of up to 30% and free XRF device demonstrations.

Contact DC Technologies to experience SpectraX today:

Website: https://dctech.com.vn/

Hotline: 0908 727 235

Showroom: 87 Nghia Thuc Street, An Dong Ward, Ho Chi Minh City

Branch: High-Tech Center, 4th Floor, HUTECH Building, D1 Street, High-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City

Branch: 22B O2 Linh Dam Peninsula, Hoang Liet Ward, Hanoi City