Chia sẻ kinh nghiệm

3 Applications of X-rays in Metal Analyzers

In modern industry, accurate and efficient metal analysis is a critical factor in ensuring product quality and process reliability. Thanks to advancements in X-ray fluorescence (XRF) technology, today’s metal analyzers can perform fast, precise, and non-destructive testing of various metal and alloy samples. This article by DC Technologies highlights the three most important applications of X-ray technology in metal analyzers, along with key concepts, operating principles, and popular XRF devices currently in use.

I. What Is a Metal Analyzer?

A metal analyzer is a specialized instrument designed to identify the elemental composition of metals and alloys, determine the concentration of individual elements, and evaluate material properties in a fast, non-destructive manner. Featuring high accuracy, ease of use, and analysis times measured in seconds, metal analyzers are widely used in sectors such as metallurgy, mechanical engineering, manufacturing, recycling, and precious metals inspection.

These tools play a vital role in quality control and help ensure compliance with technical standards in industrial production.

II. Definition of X-rays

1. What Is X-ray Fluorescence (XRF) Technology?

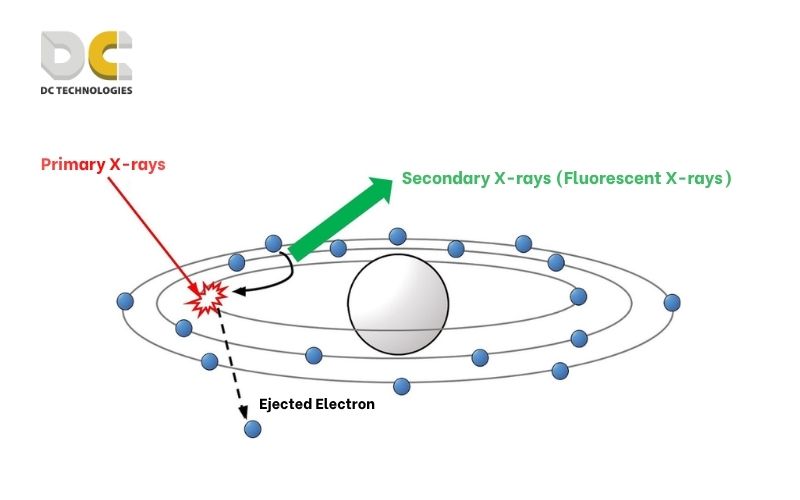

XRF (X-ray Fluorescence) is an analytical technique used to determine the elemental composition of materials by measuring the characteristic secondary (or fluorescent) X-rays emitted from a sample when it is excited by a primary X-ray source.

When high-energy X-rays are directed onto the surface of a material, atoms within the sample absorb this energy and become ionized. As electrons from higher energy levels fill the vacancies, secondary X-rays are emitted at energies that are unique to each element. By detecting and analyzing these fluorescent X-rays, the instrument can accurately identify and quantify the elements present.

2. How Do X-rays Work in Metal Analysis?

In an XRF-based metal analyzer, the primary X-ray beam (generated from the X-ray tube) interacts with the atoms in the sample. This causes inner-shell electrons (typically from the K or L shells) to be ejected. When outer-shell electrons fall into these vacancies, they emit characteristic X-rays specific to each element.

For example: If the device detects an Lα fluorescent line at 9.71 keV, the sample likely contains gold (Au). If the Lα line appears at 2.98 keV, the element is most likely silver (Ag).

This non-destructive, precise, and rapid method is particularly effective for industrial quality control and material verification.

Figure 1: Operating principle of X-rays

III. 3 Key Applications of X-ray Technology in Metal Analyzers

1. Rapid, Non-Destructive Elemental Analysis

X-ray technology allows for fast, non-destructive testing of metal components. Samples remain intact after analysis, ensuring their usability post-inspection. This saves time and cost, while delivering highly reliable results — ideal for on-site and routine inspections.

2. Jewelry and Precious Metal Authentication

XRF-based analyzers are widely used to determine purity, detect impurities, and differentiate between genuine and counterfeit precious metals such as gold, silver, and platinum. These applications are crucial for consumer protection, enhancing brand credibility, and maintaining regulatory compliance in the jewelry industry.

3. Quality Control in Industrial Production

In industrial environments, metal analyzers with X-ray technology are essential for monitoring raw material quality and ensuring final products meet required specifications. Accurate elemental analysis helps manufacturers maintain consistent product quality, reduce production errors, and optimize efficiency.

IV. Popular XRF Metal Analyzers on the Market

1. Thermo Scientific Niton XL2 – 100G

The Niton XL2 – 100G is a handheld metal analyzer from Thermo Scientific (USA), engineered with advanced X-ray fluorescence (XRF) technology. Equipped with a powerful 38kV X-ray tube, the XL2 – 100G delivers deep, fast, and stable elemental analysis for a wide range of metal applications. This device stands out for its robust performance and user-friendly design, making it ideal for both field and laboratory use.

Capable of precisely identifying and quantifying up to 25 metal elements from Titanium (Ti) to Bismuth (Bi), including commonly analyzed elements such as Cr, Mn, Fe, Co, Ni, Cu, Zn, Mo, Ag, Sn, Pb, Au, and more.

Weighing approximately 1.53 kg, the device is ergonomically designed for one-handed operation, enabling ease of use during extended field work or repetitive testing scenarios.

The XL2 – 100G offers long service life, with minimal maintenance requirements and virtually no consumables needed during operation, resulting in lower total cost of ownership.

2. SpectraX 25 Metal Analyzer

The SpectraX 25 is a metal analyzer that utilizes X-ray fluorescence (XRF) spectroscopy, a non-destructive analytical technique that requires no complex sample preparation. This makes it an ideal tool for fast and reliable elemental analysis across a variety of applications.

The device can accurately analyze up to 25 metal elements, including commonly tested elements such as Gold (Au), Silver (Ag), Copper (Cu), Zinc (Zn), Lead (Pb), and more. Results are displayed within seconds, making it particularly valuable for jewelry stores, assay laboratories, and quality control centers that require quick and precise inspections.

Equipped with a sharp LCD display and an intuitive user interface, the SpectraX 25 ensures ease of operation for users at all experience levels.

Its lightweight and compact form factor, combined with simple, straightforward operation, makes it suitable for both experienced professionals and non-technical users alike.

3. Thermo Scientific Niton XL3T

The Thermo Scientific Niton XL3T is an advanced generation of handheld metal analyzers, engineered for high-performance, on-site elemental analysis.

Figure 2: Handheld spectrometer XL3T

Featuring a powerful 50kV X-ray tube, the XL3T offers deeper penetration and faster analysis, combined with a high-resolution detector and a foldable, full-color touchscreen for flexible operation in field environments.

Detects elements from S to U, including light elements (Mg, Al, Si) using helium purge.

Features include USB/Bluetooth connectivity, touchscreen, and small-spot mode (3mm).

Perfect for field applications in mining, recycling, manufacturing, and quality assurance.

V. Why Choose DC Technologies?

As the official technology partner of Thermo Scientific in Vietnam, DC Technologies offers state-of-the-art metal analysis solutions backed by professional after-sales service, technical consultation, and authorized maintenance.

Our ongoing "Trade-In, Trade-Up" program allows customers to upgrade outdated equipment at reduced cost, accessing the latest in XRF technology while optimizing their investment and analytical capabilities.

Figure 3: DC Technology is an official partner of Thermo Scientific.

Conclusion

XRF-based metal analyzers like the Niton XL2, SpectraX 25, and Niton XL3T have become indispensable tools in the jewelry, manufacturing, and industrial inspection sectors. With their rapid, accurate, and non-destructive testing capabilities, these devices empower businesses to ensure quality, reduce waste, and enhance productivity.

Choosing the right analyzer — and the right partner — is crucial for sustainable success and optimal return on investment.

Contact us for a personalized consultation and find the right gold testing solution for your operation!

Website: https://dctech.com.vn/

Hotline: 0901 958 318

Showroom: 87 Nghia Thuc Street, An Dong Ward, Ho Chi Minh City.

4th Floor, HUTECH Building, D1 Street, Saigon Hi-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City.

22B, Block O2, Linh Dam Peninsula, Hoang Liet Ward, Hanoi City.