Chia sẻ kinh nghiệm

Basic Operating Principles of Metal Composition Analyzers

In industries such as manufacturing, metallurgy, recycling, and especially in the jewelry and precious metal industry, the analysis of metal composition plays a vital role.

Metal analyzers were developed to provide fast, accurate results, helping businesses optimize production processes, ensure product quality, and save costs.

This article will help you understand what a metal analyzer is, the basic operating principles of popular technologies, and suggest the best metal analyzer models available today, along with reputable suppliers to consider for your investment.

I. What Is a Metal Composition Analyzer?

A metal composition analyzer is a specialized device designed to accurately determine the proportion of elements present in a metal or alloy sample.

It can quickly test a wide range of metals such as gold, silver, platinum, copper, nickel, steel, aluminum, titanium, and others.

Thanks to its high accuracy and versatility, the metal analyzer has become an indispensable tool in industries that demand precision and efficiency.

>> Read more: Why Jewelry Stores Should Equip a Gold Tester

>> Read more: 7 Key Criteria When Choosing a Gold Testing Machine

II. Basic Working Principles of Metal Analyzers

Depending on the technology applied, each type of analyzer has its own unique mechanism.

However, in general, all analyzers work based on the principle of using an energy source (such as X-rays, plasma, or electric arc) to excite the atoms in the sample, causing them to emit characteristic signals.

The optical system and detectors of the device then collect and analyze these signals to determine the elemental composition of the sample.

Below are the three most commonly used technologies today:

1. OES Technology (Optical Emission Spectroscopy)

OES analyzers operate by exciting the metal sample with an electric arc or spark.

When excited, the atoms in the sample emit light radiation at specific wavelengths unique to each element.

By measuring the emitted light, the analyzer can identify and quantify the elements present.

OES is commonly used in metal production and quality control laboratories because of its speed and high accuracy when testing solid metal samples.

2. XRF Technology (X-ray Fluorescence)

The X-ray fluorescence (XRF) analyzer is the most widely used device in the jewelry and precious metals sector.

It directs a beam of X-rays onto the sample, causing atoms to emit secondary radiation (fluorescent X-rays).

The analyzer detects this fluorescence and determines the elemental composition based on the characteristic energy of the emitted rays.

XRF technology is used to identify metal types, measure gold purity (karat), and detect adulteration or alloying.

This technology is non-destructive, delivers results within seconds, and is user-friendly, making it ideal for jewelry shops and metal traders.

3. ICP Technology (Inductively Coupled Plasma)

The ICP analyzer uses a high-frequency inductively coupled plasma to ionize the sample (usually in liquid form).

Once ionized, the atoms emit light spectra that are unique to each element.

The analyzer reads these spectra to determine trace element composition with extremely high precision.

ICP technology is commonly found in research laboratories, universities, and industrial quality control centers where detailed quantitative analysis is required.

>> Read more: X-ray Fluorescence Spectrometer for Metal Analysis

>> Read more: 5 Essential Devices Every Jewelry Store Should Have

III. The Best Metal Analyzers Available Today

Globally, many reputable manufacturers produce and supply metal analyzers.

However, in Vietnam, the SpectraX series distributed by DC Technologies stands out for its modern design, stable performance, and high accuracy.

Below are some of the top-performing models:

1. SpectraX 20 – Multi-Purpose Metal Analyzer

The SpectraX 20 is designed to meet the demands of factories, processing workshops, and inspection units.

It can quickly and accurately analyze multiple elements in alloys such as steel, aluminum, and copper.

Outstanding features: High precision, fast testing speed, and simple operation.

Perfect for businesses that need strict control of input materials and product quality.

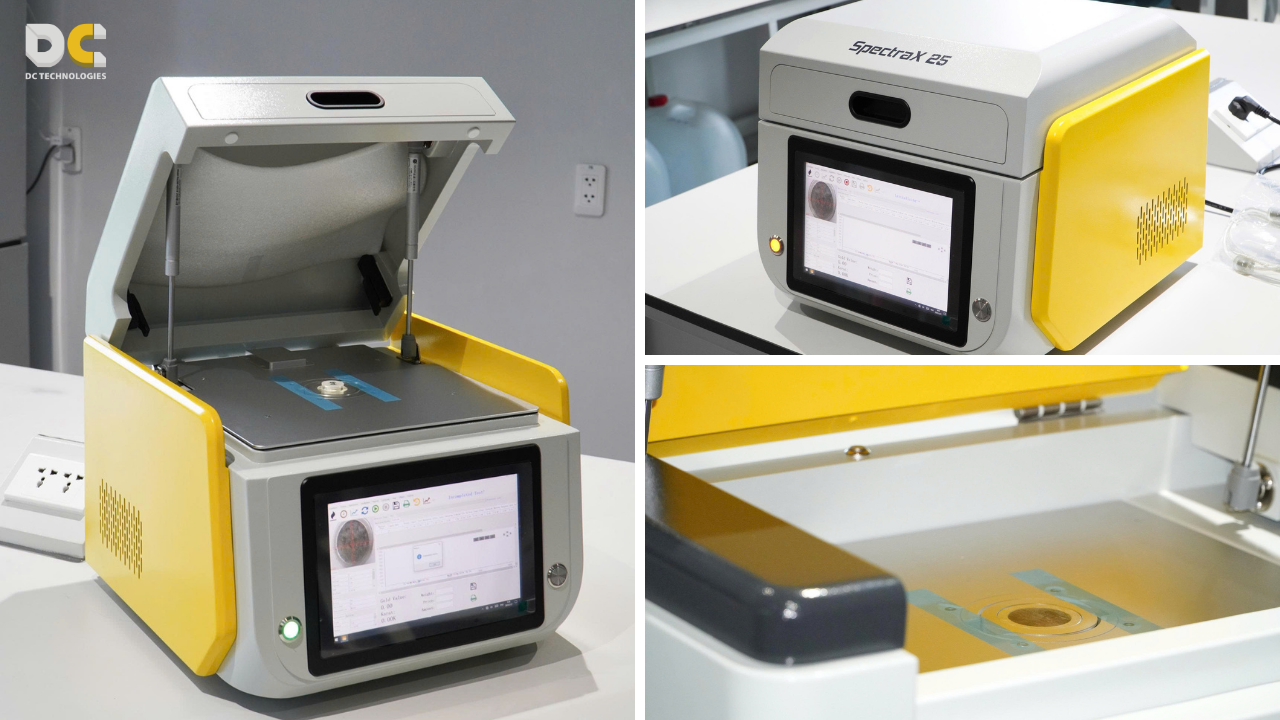

2. SpectraX 25 – Gold Testing Analyzer

The SpectraX 25 model is specifically designed for the jewelry and precious metal industry, capable of determining gold, silver, and platinum purity within just a few seconds.

It provides non-destructive, high-accuracy results, making it ideal for jewelry stores, manufacturing workshops, and gold trading facilities.

This model helps ensure transaction transparency and customer trust, two vital factors in the jewelry business.

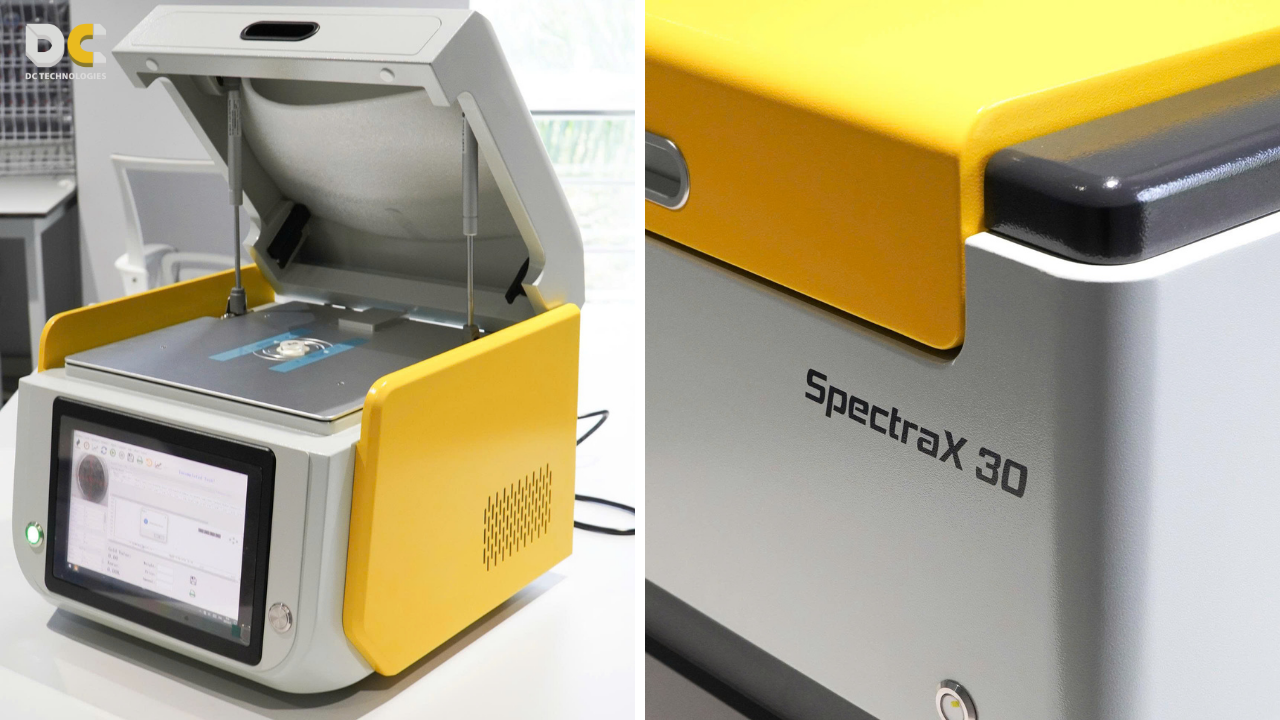

3. SpectraX 30 – RoHS Compliance Analyzer

The SpectraX 30 analyzer is developed to test RoHS compliance — especially important in electronics, electrical, and component manufacturing industries.

It can detect hazardous elements such as lead (Pb), cadmium (Cd), mercury (Hg), and chromium (Cr) in materials.

By using SpectraX 30, businesses can meet international safety standards, avoid legal risks, and enhance their global brand reputation.

4. SpectraX 55 – Coating Thickness Analyzer

The SpectraX 55 is a specialized device used in the electroplating and metal finishing industry.

It measures the thickness of metal coatings such as gold, silver, nickel, or zinc with high precision.

This allows companies to control product quality, reduce material waste, and minimize production errors.

The SpectraX 55 is ideal for plating factories, component manufacturers, jewelry producers, and electronics companies with stringent quality demands.

Special Offer from DC Technologies

DC is currently offering a “Trade-In – Upgrade” program for the SpectraX 20, 25, 30, and 55 models.

When purchasing a new analyzer, customers can trade in their old XRF machine to save costs while upgrading to the latest technology.

This is a great opportunity for businesses to optimize budgets, improve testing accuracy, and enhance operational efficiency.

Contact DC Technologies today for consultation and exclusive offers from the Trade-In – Upgrade program!

IV. How to Choose a Reliable Metal Analyzer Supplier

Selecting a trusted supplier is just as important as choosing the right analyzer.

Here are four key factors to consider before making a purchase decision:

Verified Origin and Quality Certificates

Choose analyzers with authentic documentation, certificates of origin, and official import approval to avoid counterfeit or low-quality products.

At DC Technologies, all products are genuine and internationally certified, ensuring top reliability.After-Sales Service and Warranty

Reliable suppliers must offer comprehensive after-sales support, including 12–24 months of warranty, maintenance, spare parts replacement, and regular calibration services.

DC provides fast, professional warranty response and lifetime technical assistance.Technical Support and User Training

For users who are new to analyzer operation, DC provides on-site installation, training, and technical guidance to ensure effective use from day one.Demo and Trade-In Support

DC also offers machine demonstrations, trade-in programs, and flexible pricing policies tailored to your business size and requirements.

V. Conclusion

A metal composition analyzer is an indispensable tool across many industries — from metallurgy, industrial manufacturing, and research to jewelry trading.

Understanding the OES, XRF, and ICP technologies helps businesses select the most suitable analyzer for their operational needs.

If you’re looking for a reliable, fast, and accurate metal testing solution, contact DC Technologies today.

With the SpectraX series tailored for the jewelry industry and a dedicated support team, DC guarantees trust, efficiency, and long-term value for every customer.