Chia sẻ kinh nghiệm

[MAINTENANCE] Octavelight R1 3D Printer: Cleaning the Scanning Sensor to Extend Machine Lifespan

When you own a modern 3D printer like the Octavelight R1, one essential maintenance task that can't be overlooked is cleaning the scanning sensor. However, many people may not yet realize the crucial role this component plays in the operation of a 3D printer. In this article, we’ll explore the importance of cleaning the scanning sensor and provide a detailed guide on how to clean the scanning sensor of the Octavelight R1 3D printer.

Why Clean the Scanning Sensor on the Octavelight R1 3D Printer?

The scanning sensor plays a crucial role in the operation of the Octavelight R1 3D printer, used to monitor and control the printing process. Regular maintenance and cleaning of the scanning sensor are essential. Without proper care, the sensor may encounter significant issues, such as:

Reduced Performance and Print Quality: Dust or resin residue on the sensor can reduce precision in resin level control, impacting print quality.

Operational Errors: The printer may fail to detect low resin levels, leading to interrupted prints or flawed models.

High Maintenance Costs: If the scanning sensor becomes too damaged to function, replacing it with a new sensor can be costly.

In short, regular care and cleaning of the scanning sensor help the printer perform better, extend its lifespan, minimize errors, and save on repair or replacement costs.

The Breakthrough Difference of Bottom-Mounted Platform Technology

The Octavelight R1 3D printer, featuring a bottom-mounted platform, introduces significant advances that traditional suspended platform technology has not achieved. Key benefits include:

Maximum Resin Savings: With minimal support requirements, the Octavelight R1 minimizes resin consumption.

No Tray Replacement Needed: The printer is designed to use a lifetime tray, reducing costs, material waste, and the time spent replacing trays.

Simplified Operation: A single calibration enables long-term use without complex adjustments.

How to Check and Clean the Scanning Sensor

Before cleaning the scanning sensor, gather the necessary items to ensure a smooth and effective process. Here’s what you’ll need:

Soft Tissue Paper: Choose fine, soft tissue to avoid scratching the sensor glass.

Specialized Lens Cleaning Cloth: Use a high-quality lens cloth to clean the sensor surface without leaving scratches or dust.

Glass Cleaning Solution or Dish Soap: Avoid alcohol-based solutions, as they may damage the sensor’s glass coating.

Laptop: Connect the laptop to the printer to check the sensor’s status and make any necessary adjustments.

Once all items are ready, you can proceed with checking and cleaning the scanning sensor.

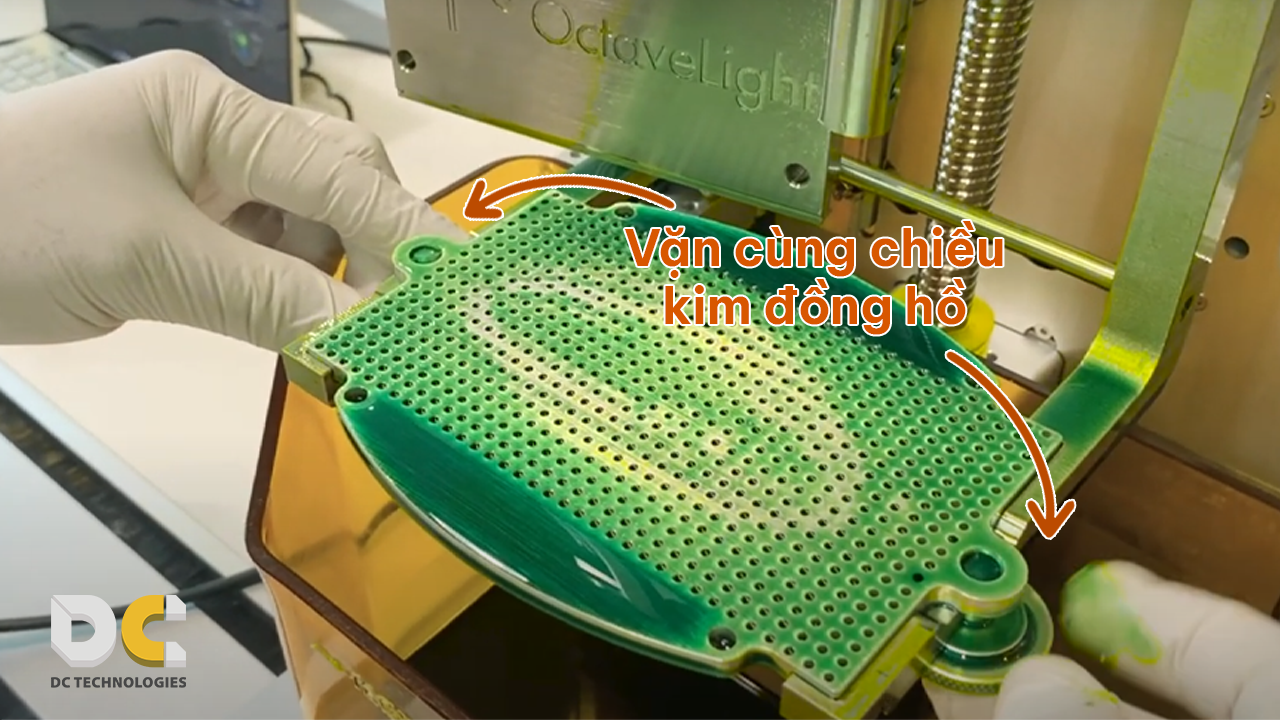

Step 1: Platform removal

One of the key reasons to remove the platform is that when the platform comes into contact with the resin surface, it can create bubbles. These bubbles may interfere with the platform, leading to inaccurate measurements in the software and incorrect assessments of the machine's status. To address this, we proceed to step 2.

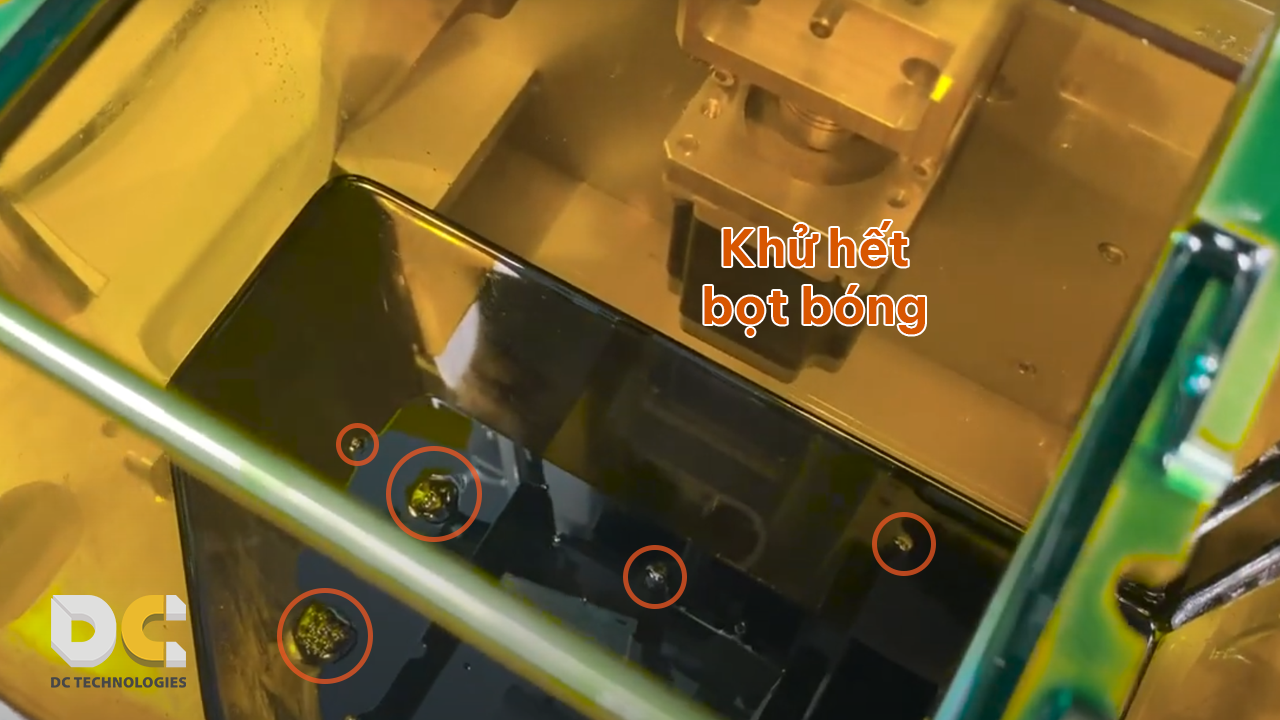

Step 2: Eliminate all bubbles inside the resin tank.

In this step, use the prepared tissue to wipe away all bubbles inside the resin tank.

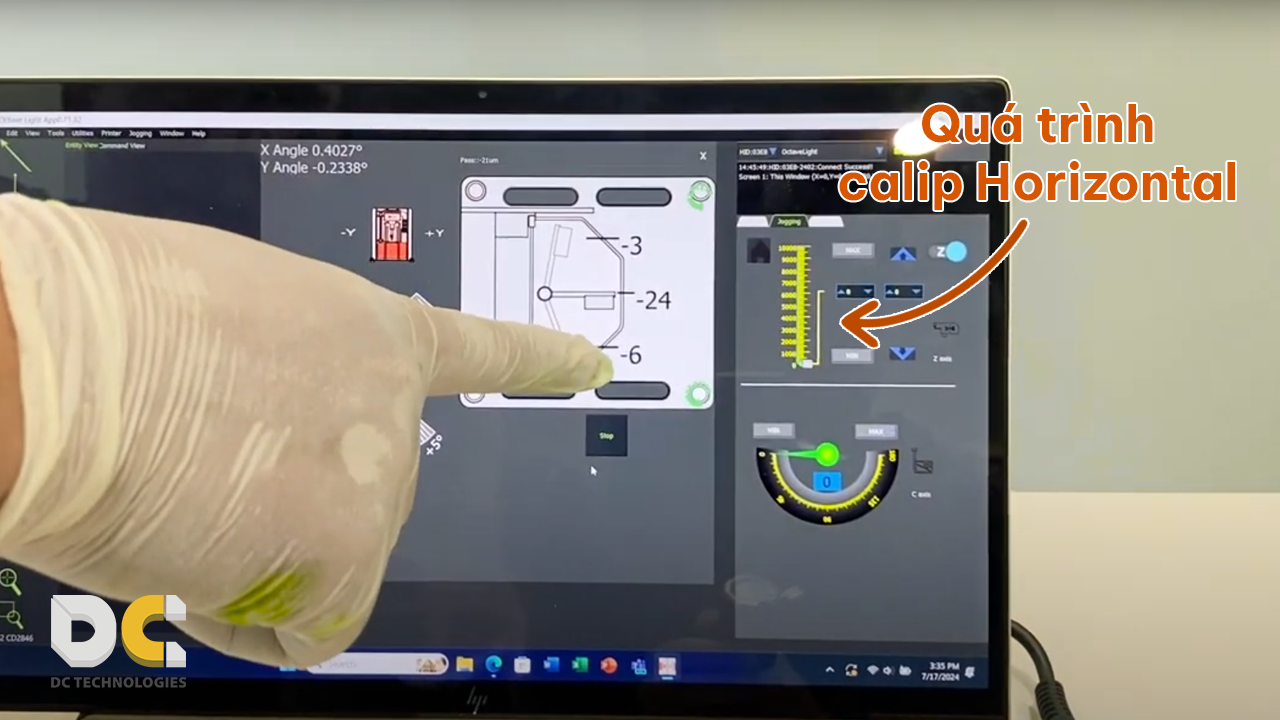

Step 3: Perform Horizontal Calibration

The next step is to perform the Horizontal Calibration, a crucial process to determine if the sensor is functioning properly. The purpose of Horizontal Calibration is to check the sensor's measuring capability by observing feedback results at different positions on the resin surface, then analyzing the information on the laptop.

Identifying Error Results: If the measurement value at one position spikes significantly compared to the other two positions, it may indicate an issue.

Note: During the calibration process, be mindful of minimizing any vibrations on the table surface. This movement can cause the resin surface to shift, leading to inaccurate readings and potentially misleading you to think the sensor is faulty. Failing to accurately assess the situation might lead to unnecessary repair or replacement costs for the sensor.

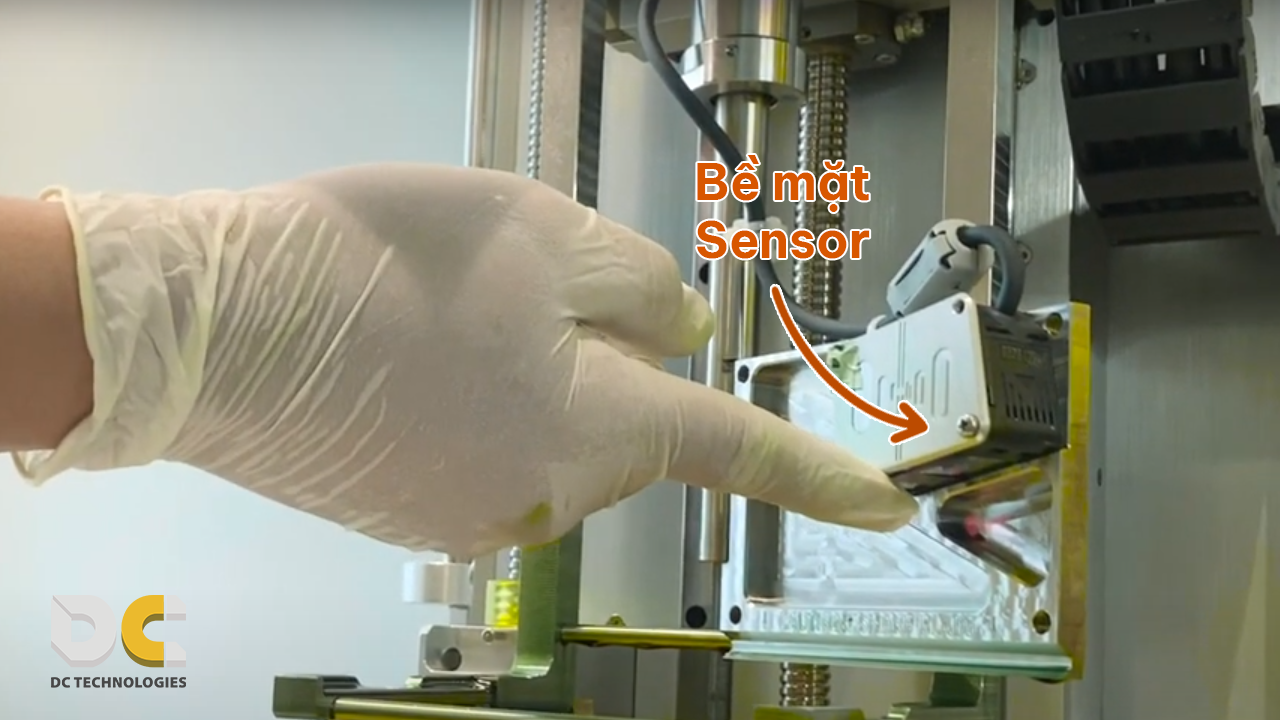

Step 4: Clean the sensor surface

The next step is to clean the surface of the glass layer beneath the sensor, an important area where the sensor receives signals. Start by using a soft tissue to gently wipe the glass surface, making sure to wipe in one consistent direction to avoid scratches or damage to the glass layer.

After the initial wipe with tissue, continue with a specialized glass cleaning cloth and some dishwashing liquid to thoroughly clean the surface. Keep in mind that incorrect cleaning methods can leave stains or damage the glass surface.

With these steps, DC Tech has provided you with a clear guide on how to clean the scanning sensor of the Octavelight R1. If you need any further assistance, don’t hesitate to contact us!

For more details, you can watch the instructional video at: https://www.youtube.com/watch?v=YMq1oeV_Xd0&t=269s