PALLUNA® 4700 is a chloride-free, ammonia-reduced high-speed electrolyte for the deposition of a semi-bright to bright palladium-nickel alloy in reel-to-reel lines...

For hard and wear resistant coatings

PALLUNA® 4700 is a chloride-free, ammonia-reduced high-speed electrolyte for the deposition of a semi-bright to bright palladium-nickel alloy in reel-to-reel lines (selective dipping, jet plating, brush plating) and tabplaters.

Depending on the operating conditions, the electrolyte deposits alloy layers with approx. 80% of Pd. The alloy composition is largely independent of the current density.

The hard and wear-resistant layers are ductile, with low internal stresses and exhibit good corrosion resistance.

Electrolytes Characteristics

| Electrolyte type | Chloride-free ammoniacal |

| Metal content | 20 g/l Pd, 15 g/l Ni |

| pH value | 7.7 |

| Operating temperature | 40 °C |

| Current density range | up to 50 A/dm² in JetLab |

| Plating speed | up to 12 μm/min in JetLab |

| Anode material | Platinized titanium (e.g. PLATINODE®) |

Coating Characteristics

| Coating | Palladium nickel |

| Purity | 80 wt.% Pd, 20 wt.% Ni |

| Brightness | Semi-bright to bright |

| Hardness of deposit | approx. 550 HV kp/mm² (5mN load) |

| Density of the coating | ca. 10,8 g/cm³ |

Advantages

- Chloride-free

- pH and ammonia reduced

- High deposition rate

- Ductile coatings

- Constant alloy composition

Applications

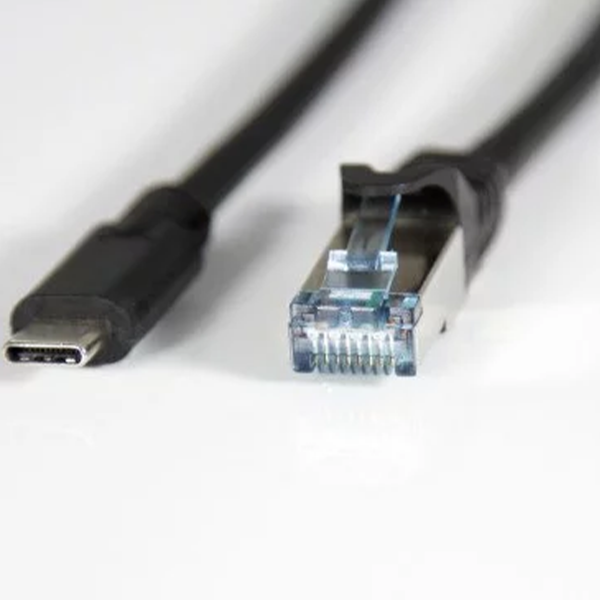

- Industrial connectors (data and signal transmission)

- IT connectors (e.g. USB-C)