Chia sẻ kinh nghiệm

Metal Plating Process Using International Standard Chemicals

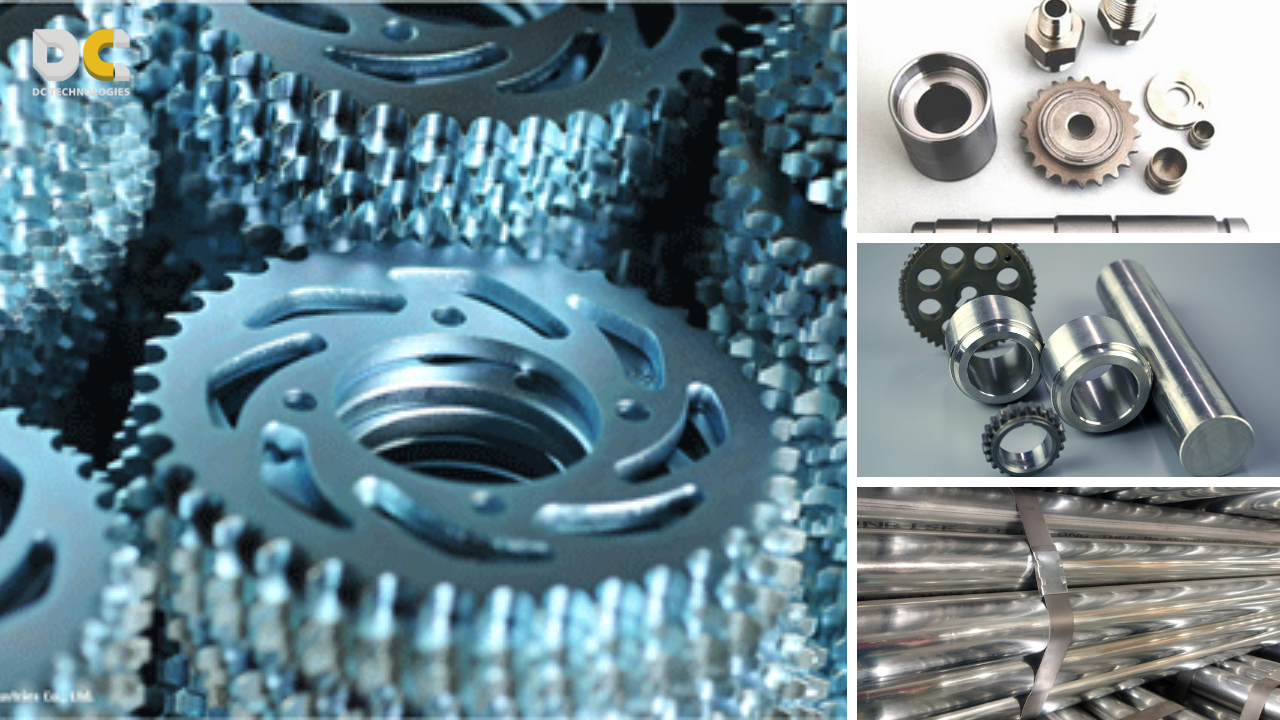

In today’s industrial era, metal plating is not merely about creating a shiny appearance for products, but also a solution to enhance durability, prevent oxidation, and meet strict international standards. Especially, when using international standard plating chemicals, businesses not only ensure superior product quality but also move towards sustainable, safe, and environmentally friendly development. This article will help you better understand the international standard plating process, its benefits, and how to choose a reliable chemical supplier in Vietnam.

I. What is Chemical Metal Plating?

Chemical metal plating is the process of coating a thin layer of metal onto the product surface through chemical or electrochemical reactions. The purpose of plating goes beyond improving the aesthetics of products; it also enhances mechanical strength, oxidation resistance, corrosion resistance, and other technical properties. Therefore, plating chemicals play a crucial role in the plating process.

II. Why Use International Standard Chemical Metal Plating?

Using international standard plating chemicals is increasingly becoming an inevitable trend for several important reasons. First, international standard chemicals undergo strict quality control, ensuring a durable, shiny, and long-lasting plated layer that is resistant to peeling. This helps extend product lifespan, especially for items exposed to harsh environments.

In addition, certified chemicals deliver superior aesthetics. Plated products achieve a uniform coating, natural color, and long-lasting beauty—an essential factor in the jewelry and handicraft industries.

Another significant reason is safety and environmental friendliness. Traditional chemicals often contain harmful substances that negatively impact workers’ health and pollute the environment. Meanwhile, international standard chemicals are produced using advanced technology, reducing toxins and complying with global environmental standards.

>> Read more: What Are Plating Chemicals? Applications in the Jewelry Industry

>> Read more: What is Electroplating? The Most Common Plating Technologies Today

III. International Standard Metal Plating Process with Chemicals

The international standard metal plating process is not only about applying a metal layer onto the product surface, but also a series of scientific and strict steps to ensure durability, aesthetics, and user safety. The basic steps include:

1. Surface Treatment

Before plating, the metal surface must be completely cleaned using specialized cleaning chemicals. The goal is to remove oil, dust, rust, and impurities, creating a smooth surface that improves adhesion of the plating layer.

2. Surface Activation

After cleaning, the product undergoes surface activation using specific chemical solutions. This step makes the surface more “active,” facilitating the bonding of the plated metal layer.

3. Plating Process

The product is immersed in a plating bath containing chemical solutions and metal ions (gold, silver, rhodium, nickel, etc.). Through the action of electricity (electroplating) or chemical reactions (chemical plating), the metal ions firmly adhere, forming a uniform, shiny, and durable coating.

4. Post-Plating Treatment

After plating, the product is rinsed with deionized water and may undergo additional surface treatments such as polishing or applying a protective anti-oxidation coating. This step not only improves durability but also enhances product aesthetics.

5. Quality Inspection

Finally, the product is tested according to international standards. Evaluation criteria include plating thickness, adhesion, corrosion resistance, and uniformity. Only certified products are allowed to enter the market or be exported.

>> Read more: Classification of Plating Chemicals: Gold, Silver, Rhodium, and Nickel

>> Read more: International Standard Gold Plating with Specialized Chemicals

IV. Where to Source International Standard Plating Chemicals

1. Criteria for Choosing a Supplier

To achieve high efficiency in plating, selecting a reliable chemical supplier is key. Businesses should consider:

Clear origin: Chemicals must come with certificates of origin, with transparency in import and distribution.

Certified quality: Prioritize products that meet international standards and include safety and environmental certifications.

Professional technical support: A reputable supplier provides engineers and experts to advise, guide, and troubleshoot during production.

Long-term after-sales service: Beyond product supply, a reliable partner accompanies businesses throughout the production process to optimize costs and efficiency.

>> Read more: Guide to Selecting High-Quality Electroplating Chemicals

>> Read more: What is Gold Salt? Properties and Applications in Plating

2. International Standard Chemical Suppliers in Vietnam

In Vietnam, DC Technologies is the official distributor of Umicore (Germany)—a global leader in chemicals and advanced materials. Umicore is internationally renowned for its certified, eco-friendly products widely applied across industries.

DC not only supplies high-quality plating chemicals but also partners with businesses by providing technical consulting and optimal production solutions.

DC’s commitments include:

High-quality products meeting international standards.

Safe, environmentally friendly chemicals.

Professional technical consulting from expert teams.

Reliable after-sales service, supporting businesses in the long run.

If you are looking to purchase international standard plating chemicals in Vietnam, contact DC for dedicated advice and support. This is the safe, high-quality, and sustainable choice for businesses in jewelry, electronics, and precision engineering industries.

V. Conclusion

Metal plating with international standard chemicals offers outstanding benefits: durable and aesthetic plating quality, oxidation resistance, and compliance with strict global standards. This trend helps businesses strengthen brand reputation and expand export opportunities.

Choosing certified chemicals and a trusted supplier like DC - the official partner of Umicore in Vietnam - is the key to ensuring production efficiency and sustainable growth. Investing correctly from the chemical selection stage is the way to create differentiation and affirm market position.