Tin công nghệ

What is Gold Salt? Finding Its Properties and Applications in Electroplating

In the field of metal electroplating, gold salt is considered an indispensable material for creating durable, aesthetically pleasing gold coatings with excellent conductivity and strong resistance to oxidation. Thanks to its outstanding properties, gold salt is not only used in the jewelry industry but also in electronics, healthcare, and high technology. So, what exactly is gold salt, what are its chemical characteristics, what functions does it serve, and where is it applied? Let’s explore in detail in the article below.

I. What is Gold Salt?

1. Definition of Gold Salt

Gold salts are chemical compounds that contain gold ions (Au) in the form of salts. They typically exist as solid crystals that are easily soluble in plating solutions, providing the necessary gold ions for the electroplating or chemical plating process.

In the electroplating industry, gold salts serve as the main source of gold for forming a gold coating on base metals such as silver, copper, nickel, and stainless steel. Thanks to their solubility and stability in solution, gold salts ensure that the plating process proceeds evenly, producing a smooth, high-quality finish.

>> Read more: Applications of Precious Metal Electroplating in Handicraft Production

2. Chemical Properties

Solubility: Gold salts dissolve easily in electrolytic solutions, releasing gold ions (Au⁺ or Au³⁺) for electroplating.

Stability: They possess high stability, ensuring that the gold layer adheres firmly to the base metal.

Ion dissociation: They dissociate gold ions efficiently, enabling coatings with superior adhesion and brilliance.

Compatibility with various technologies: Gold salts can be used in electroplating, chemical plating, or other advanced plating techniques.

II. Functions of Gold Salt in Gold Electroplating

1. Creating durable and beautiful gold coatings

Gold salts provide gold ions that allow the coating to adhere firmly and evenly to the surface of the base metal. The resulting gold layer has a natural metallic luster, is shiny, and offers high aesthetic value. This is why gold salts are widely used in the jewelry and handicraft industries.

2. Corrosion and oxidation resistance

Gold is chemically inert; it does not oxidize or corrode under normal environmental conditions. As a result, gold plating made from gold salts protects the base metal and extends the product’s lifespan, especially in industries requiring high chemical durability.

3. Enhancing electrical conductivity and signal transmission

One of gold’s most remarkable advantages is its ability to conduct electricity and transmit signals reliably. Therefore, gold salts are applied in the plating of electronic components, circuit boards, and connectors to ensure efficient power and data transmission while reducing oxidation-related interruptions.

>> Read more: Umicore Gold Electroplating Chemicals for Premium Plating Quality

>> Read more: Gold Stripper 647 – Safe and Optimized Gold Stripping Solution

III. Common Types of Gold Salts Used in Gold Electroplating

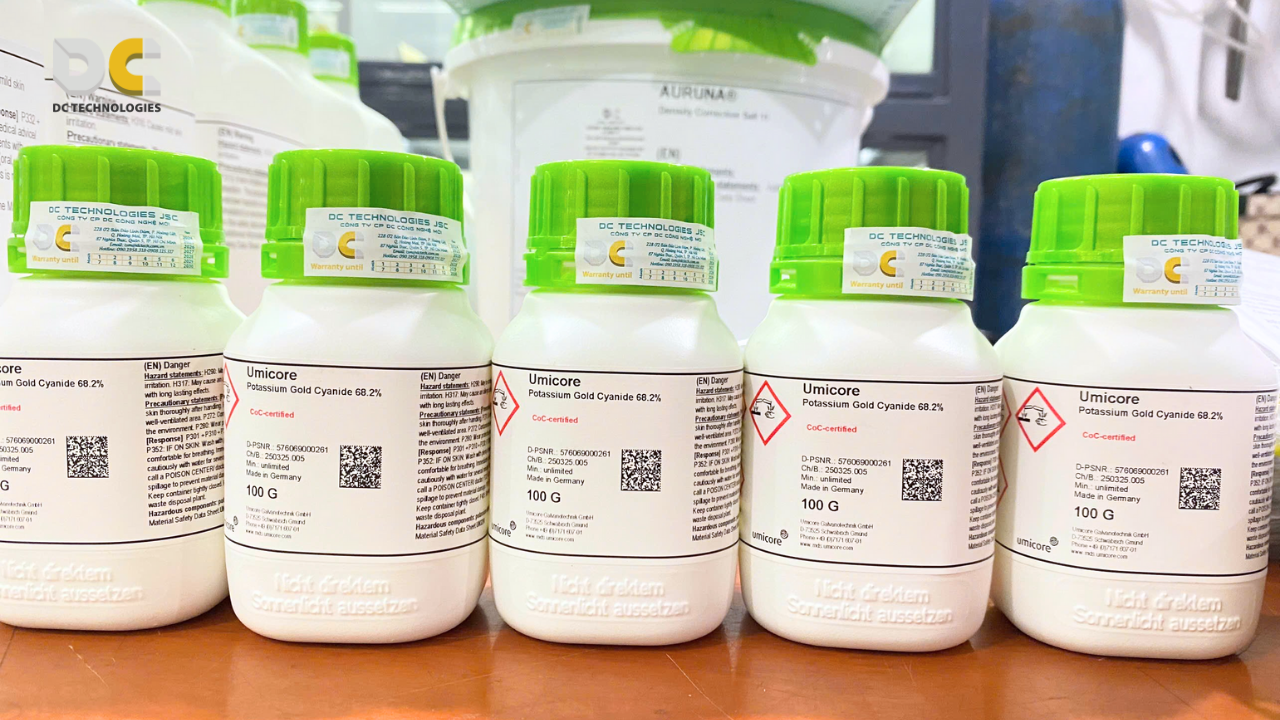

1. Potassium Gold Cyanide 68.2%

Potassium gold cyanide 68.2% is a specialized chemical widely used in electroplating. With its high gold content (68.2%), this salt enables the creation of durable, attractive coatings that meet international quality standards.

This product dissolves quickly in water, ensuring smooth and efficient plating. Thanks to its high gold content, it provides exceptional commercial value, particularly for products demanding high purity and superior aesthetics. Additionally, this salt remains stable at room temperature, decomposes above 200°C, and is safe for storage and transport when handled according to regulations for cyanide-containing chemicals.

2. Potassium Dicyanoaurate K[Au(CN)₂]

![Potassium Dicyanoaurate K[Au(CN)₂]](https://dctech.com.vn/img/cms/N58/Blog-dc-gold-salt-N58-3.png)

Potassium dicyanoaurate K[Au(CN)₂] is the most commonly used gold salt in electroplating due to its high stability and ease of control in plating baths. It produces smooth, tightly adherent gold coatings with minimal impurities, ensuring both aesthetics and quality. However, because it contains cyanide—a highly toxic compound—strict safety procedures and environmental protection regulations must be followed to avoid risks to human health and ecosystems.

3. Gold Chloride (AuCl₃, Na[AuCl₄])

Gold chloride (AuCl₃, Na[AuCl₄]) is a popular alternative for non-cyanide gold plating technologies, regarded as safer for both the environment and human health. It dissolves well in solution, yielding bright, even, and highly aesthetic gold coatings. Thanks to these advantages, gold chloride is often applied in high-end jewelry manufacturing and in modern electronics production, where both surface quality and technical precision are critical.

4. Other types of gold salts

Besides the above, several other gold salts are studied and applied in chemical plating or specialized fields, such as gold sulfite (Au₂(SO₃)₃). Though less common, they provide more environmentally friendly and safer gold-plating options.

IV. Applications of Gold Salt in Gold Electroplating

1. Jewelry Industry

Used for plating on silver, copper, and alloys to create luxurious, shiny, and high-value jewelry.

Enhances aesthetics while protecting the base metal from oxidation.

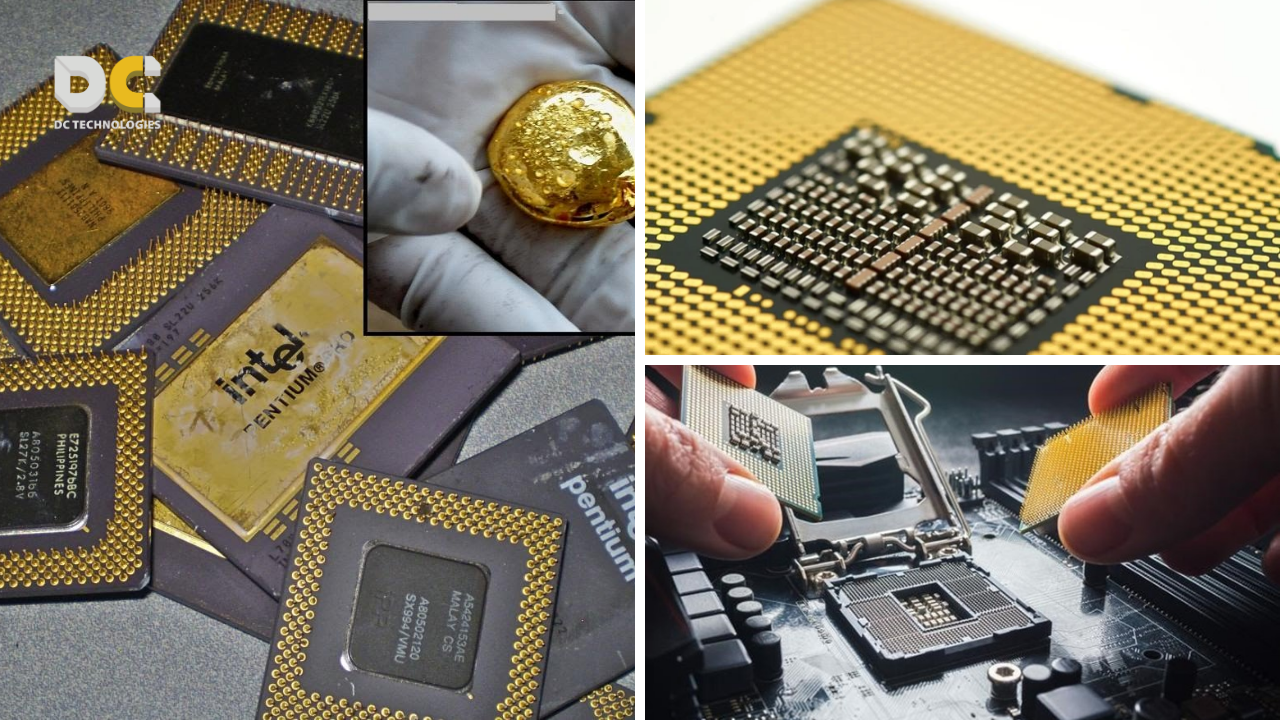

2. Electronics & Telecommunications

Gold plating for circuit boards, microchips, connectors, and processing units.

Ensures efficient electrical conductivity and fast, stable signal transmission.

Extends the service life of components under harsh conditions.

3. Medical & Dental Industry

Applied in the production of surgical instruments and medical implants.

Used in dentistry for plating dentures or implants to improve durability and biocompatibility.

4. High-Tech Industry

Used in aerospace, satellite production, and precision sensors.

Gold coatings enhance durability and stability in extreme environments where other metals corrode easily.

>> Read more: Auruna 215 Premium Gold Plating Solution – Safe and Long-Lasting Color

>> Read more: Plateen Gold Plating Machine – Genuine Italian Technology

V. Where to Buy Reliable Gold Salts for Electroplating?

To achieve the best results in electroplating, choosing high-quality gold salts is crucial. When purchasing, businesses should consider:

Trusted suppliers: Ensure clear certification of origin and quality.

Genuine products: Meet international standards for safety and efficiency.

After-sales and technical support: Suppliers should provide usage support, bath maintenance, and plating technology consultation.

Where to buy premium gold salts for electroplating?

In Vietnam, DC Technologies is one of the leading providers of high-quality electroplating chemicals, including potassium gold cyanide 68.2% from Umicore (Germany)—a world-renowned corporation. DC is committed to providing customers with:

High-quality, eco-friendly gold salts.

Dedicated technical consulting services.

Long-term support throughout production to help businesses optimize costs and efficiency.

Contact DC today for consultation on gold electroplating chemicals!

VI. Conclusion

Gold salts are the core material in gold electroplating, enabling the creation of durable, oxidation-resistant, and highly conductive coatings. With a variety of options—from cyanide-based to chloride-based salts—businesses can choose the most suitable solutions for their production needs and safety requirements.

To achieve optimal results, enterprises should purchase gold salts from reputable suppliers like DC, ensuring both product quality and expert technical support.

Frequently Asked Questions

Is electroplating gold salt toxic?

How is the application of gold salt in electronics different from jewelry?

What is the difference between potassium gold cyanide 68.2% and potassium dicyanoaurate K[Au(CN)₂]?

Where can I buy gold salts for electroplating?

How much does gold salt cost?