Altough PLATUNA® PT is highly acidic, it has a low sulphuric acid content, making it less aggressive towards the substrate to be coated. Furthermore, it has a deposition speed of approx. 0.13...

Modern platinum layers for a sustainable future

Altough PLATUNA® PT is highly acidic, it has a low sulphuric acid content, making it less aggressive towards the substrate to be coated. Furthermore, it has a deposition speed of approx. 0.13 μm/min at 5 A/dm², independent of the current intensity. The very long shelf life compared to many conventional platinum electrolytes (no precipitation) and the ease of transportation and storage (no cooling required) enable large storage quantities and thus a forward-looking cost calculation.

PLATUNA® PT coatings are suitable for a wide range of technical applications, e.g. as a catalyst in electrolysers for hydrogen production: Platinum accelerates the hydrogen evolution reaction at the cathode and reduces the amount of energy required for the reaction. PLATUNA® PT can be deposited directly onto the carrier material (ideally titanium or nickel) and produces a very thin and homogeneous platinum layer.

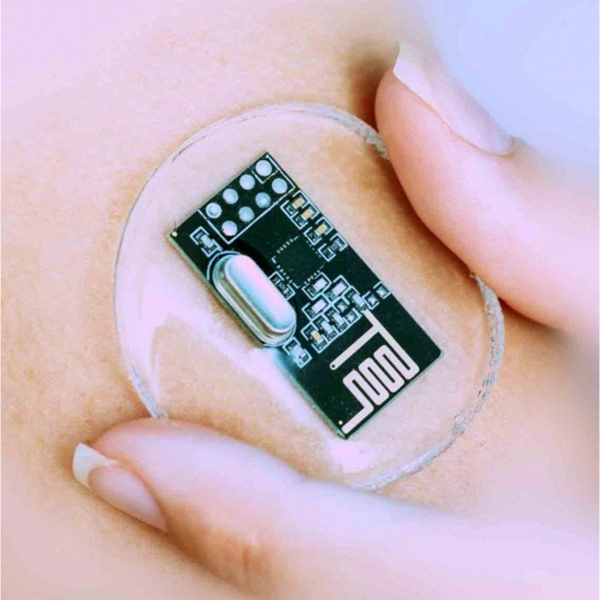

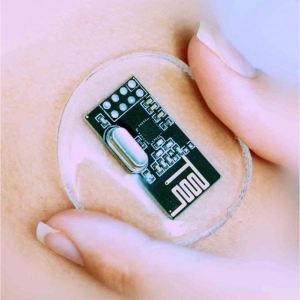

Platinum is also ideally suited as a surface material in medical sensors, as it is biocompatible, corrosion-resistant and electrically conductive. PLATUNA® PT coatings are therefore used on electrodes, catalysts or receptors in various devices such as ECG, glucose, oxygen or pH sensors.

Electrical contact surfaces, for example in connectors, also benefit from this. The platinum layer reduces the contact resistance between the contacts and increases corrosion and abrasion resistance. PLATUNA® PT can thus improve the performance and service life of electronic, industrial and automotive plug contacts.

Electrolytes Characteristics

| Electrolyte type | Strongly acidic |

| Metal content | 2 (1 - 6) g/l |

| pH value | < 1 |

| Operating temperature | 60 (55 - 65) °C |

| Current density range | 5 (0.5 - 10) A/dm² |

| Plating speed | approx. 0.13 μm/min at 5 A/dm² |

| Deposition rate | approx. 5.6 mg/Amin at 5 A/dm² |

Coating Characteristics

| Coating | Platinum |

| Purity | 99.9 wt.% Pt |

| Colour of deposit | White |

| Brightness | Bright, brilliant |

| Hardness of deposit | not measurable, approx. 350 HV |

| Max. coating thickness | approx. 0.5 μm bei 2 g/l Pt content, up to 5 μm at 6 g/l Pt content |

| Density of the coating | approx. 21,4 g/cm³ |

Advantages

- Crack-free layers up to 5 μm

- Very uniform thickness distribution with a density of 21.4 g/cm³

- Hardness of approx. 350 HV

- Absolutely fog-free, without colour cast, very bright (L* value:87) and glossy

- High abrasion resistance

- Excellent corrosion resistance

- Very good tarnish resistance

Applications

- Catalyst in electrolysers

- Sensor in the medical environment

- Contacts in connectors

- Water purification or process control systems