The ARGUNA® ET-S silver electrolyte is an alkaline-cyanide process specifically developed for use in high-speed equipment for reel-to-reel silver plating...

High-speed electrolyte for reel-to-reel plating

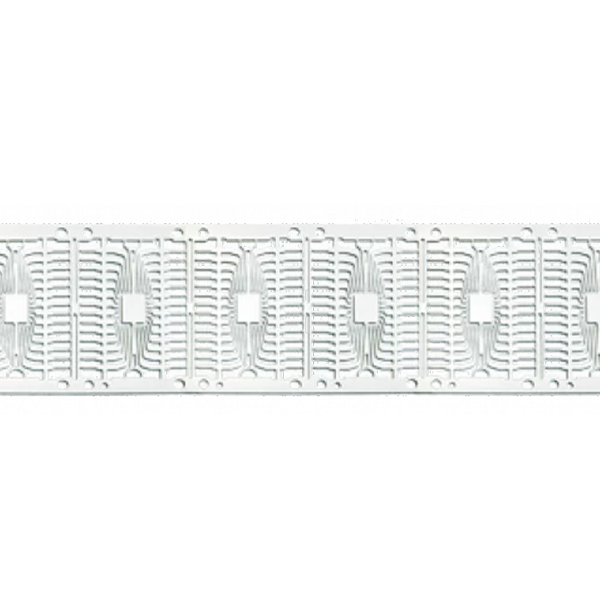

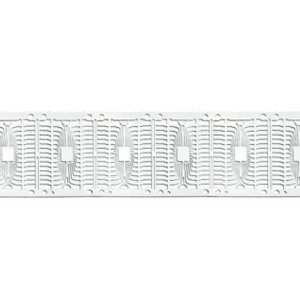

The ARGUNA® ET-S silver electrolyte is an alkaline-cyanide process specifically developed for use in high-speed equipment for reel-to-reel silver plating (using flow or spray technologies). The process deposits smooth and fine-grained, semi-bright coatings which are particularly suitable for semiconductor technology.

Current density and plating speed depend on the electrolyte agitation at the parts, i.e. on the equipment used. High electrolyte flow allow very high current densities.

Electrolytes Characteristics

| Electrolyte type | alkaline-cyanide |

| Metal content | 100 g/l Ag |

| pH value | 12.5 |

| Operating temperature | 30 - 75 °C (optimum 35 °C) |

| Current density range | 10 - 150 A/dm² |

| Plating speed | 0.2 - 1.5 μm/s |

| Anode material | Fine silver or MMO (type PLATINODE® 167 or 177) |

| Electrical conductivity | >50 m*(Ω*mm²)-1 |

Coating Characteristics

| Coating | Fine silver |

| Purity | 99.9 wt.% Ag |

| Colour of deposit | White |

| Brightness | Semi-bright |

| Hardness | 110 HV (as plated) |

| Max. coating thickness | 100 μm |

Advantages

- High-speed electrolyte for full and selective deposition of fine silver

- For reel-to-reel plating using flow or spray technologies

- Semi-bright coatings with very good soldering and bonding properties

- Use of soluble anodes possible

Applications

- Contact surfaces for electrical and electronic components