Chia sẻ kinh nghiệm

TOP MOST POPULAR METAL ANALYZERS TODAY

In the era of Industry 5.0, metal quality control has become more essential than ever. Whether you are a jewelry manufacturer, mechanical workshop, or metallurgical enterprise, investing in a metal analyzer is a smart decision to ensure high accuracy, fast analysis speed, and optimized production efficiency. Join DC Technologies to explore the most popular metal analyzers on the market today, trusted solutions that help businesses achieve precise material verification and sustainable production quality.

I. What Is a Metal Analyzer?

A metal analyzer is a scientific instrument that uses advanced analytical methods such as X-ray fluorescence (XRF) to determine the elemental composition of metals and alloys.

Beyond accurately identifying the proportion of elements such as Au, Ag, Cu, Ni, Zn, and Fe, this device serves as a powerful tool for testing the purity of gold and silver, verifying materials, and ensuring product quality control.

II. Operating Principle of XRF Metal Analyzers

XRF (X-ray Fluorescence Spectroscopy) is a qualitative and quantitative analytical technique used to determine the elemental composition of materials by measuring the fluorescent X-rays emitted from atoms when they are excited by high-energy X-rays.

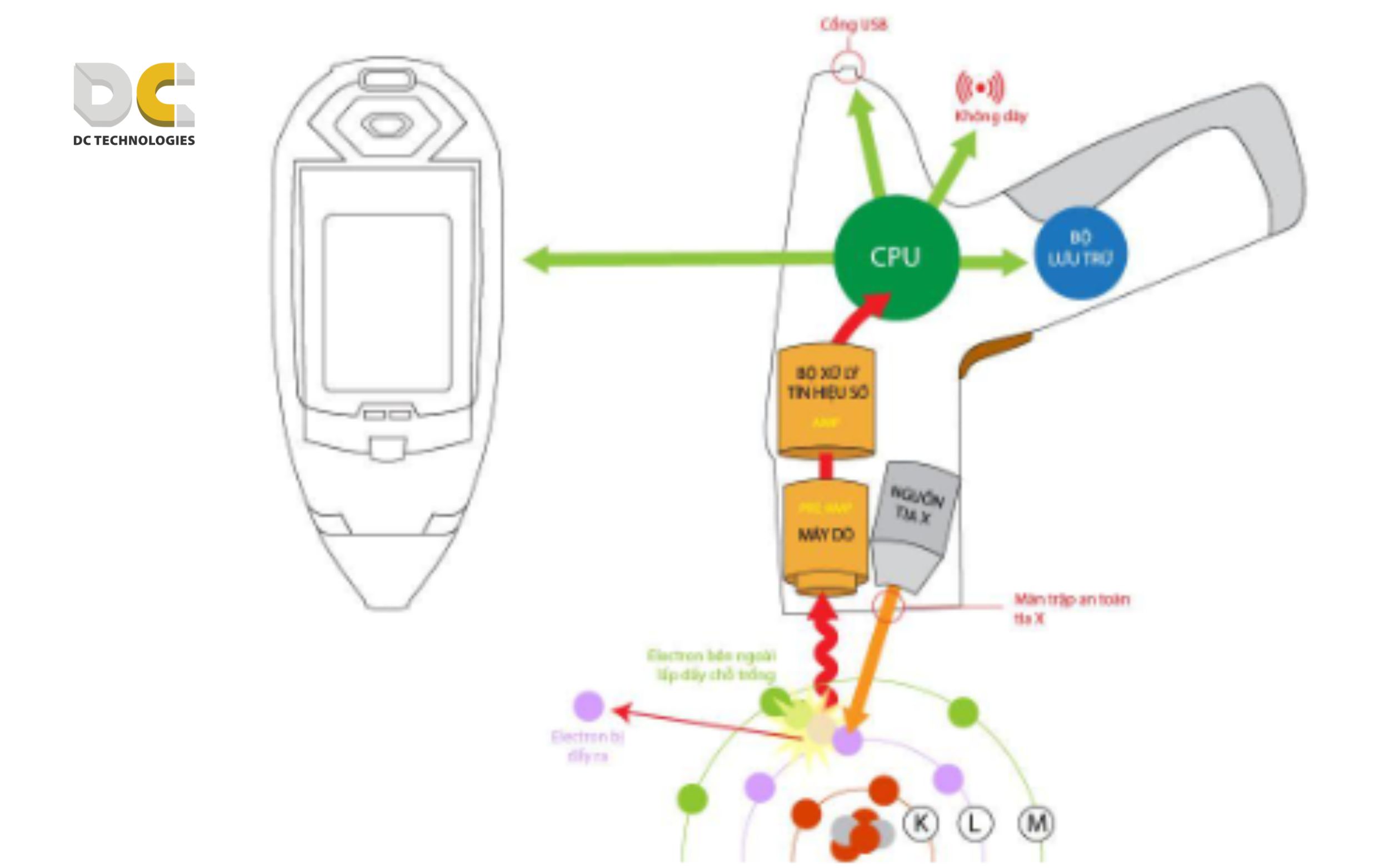

Figure 1: Basic structure of an XRF metal analyzer

An XRF metal analyzer operates based on a well-established physical phenomenon: when a beam of X-rays irradiates a sample, the high-energy photons eject inner-shell electrons from the atoms. As outer-shell electrons move down to fill these vacancies, they emit secondary X-rays (fluorescent X-rays) with energies characteristic of each element. These secondary X-rays are then detected by a detector, converted into electrical signals, and processed by specialized software. The software analyzes the energy spectrum of the detected X-rays to identify which elements are present in the sample and determine the percentage composition of each element with high accuracy.

III. Popular Metal Analyzers on the Market Today

1. Handheld Metal Analyzer Niton XL2 100G

The Niton XL2–100G is a handheld metal analyzer from Thermo Scientific (USA), renowned for its combination of high analytical performance and user-friendly design. The device employs X-ray fluorescence (XRF) technology with a 38kV X-ray tube, providing deep, fast, and stable analysis results.

- Fast, non-destructive analysis: One of the greatest advantages of the Niton XL2–100G is its ability to analyze samples without cutting, grinding, or damaging them. Within just 3–10 seconds, users can instantly view the analysis results directly on the device’s display.

- Smart data connectivity: The analyzer supports USB, Bluetooth, and RS-232 connections, allowing users to export data files to computers, print reports, or synchronize analysis results with internal systems. The integrated Niton Data Transfer (NDT) software enables custom report generation, the addition of company logos, and user access control for streamlined data management.

- Analysis of up to 25 metal elements: Capable of accurately analyzing 25 metallic elements from Titanium (Ti) to Bismuth (Bi), including common metals such as Cr, Mn, Fe, Co, Ni, Cu, Zn, Mo, Ag, Sn, Pb, and Au. This makes the Niton XL2–100G a versatile tool suitable for a wide range of applications, from heavy industry to precious metal inspection.

- Compact, durable, and ergonomic design: With an ergonomic build and a weight of only 1.53 kg, the Niton XL2–100G is easy to operate with one hand. Its intuitive color touchscreen allows for effortless use, even for non-experts. Designed with an IP54 rating for dust and splash resistance, the device performs reliably in harsh environments such as mechanical workshops, mining sites, and metallurgical plants.

Figure 2: Niton XL2 metal analyzer

2. SpectraX 25 Metal Analyzer

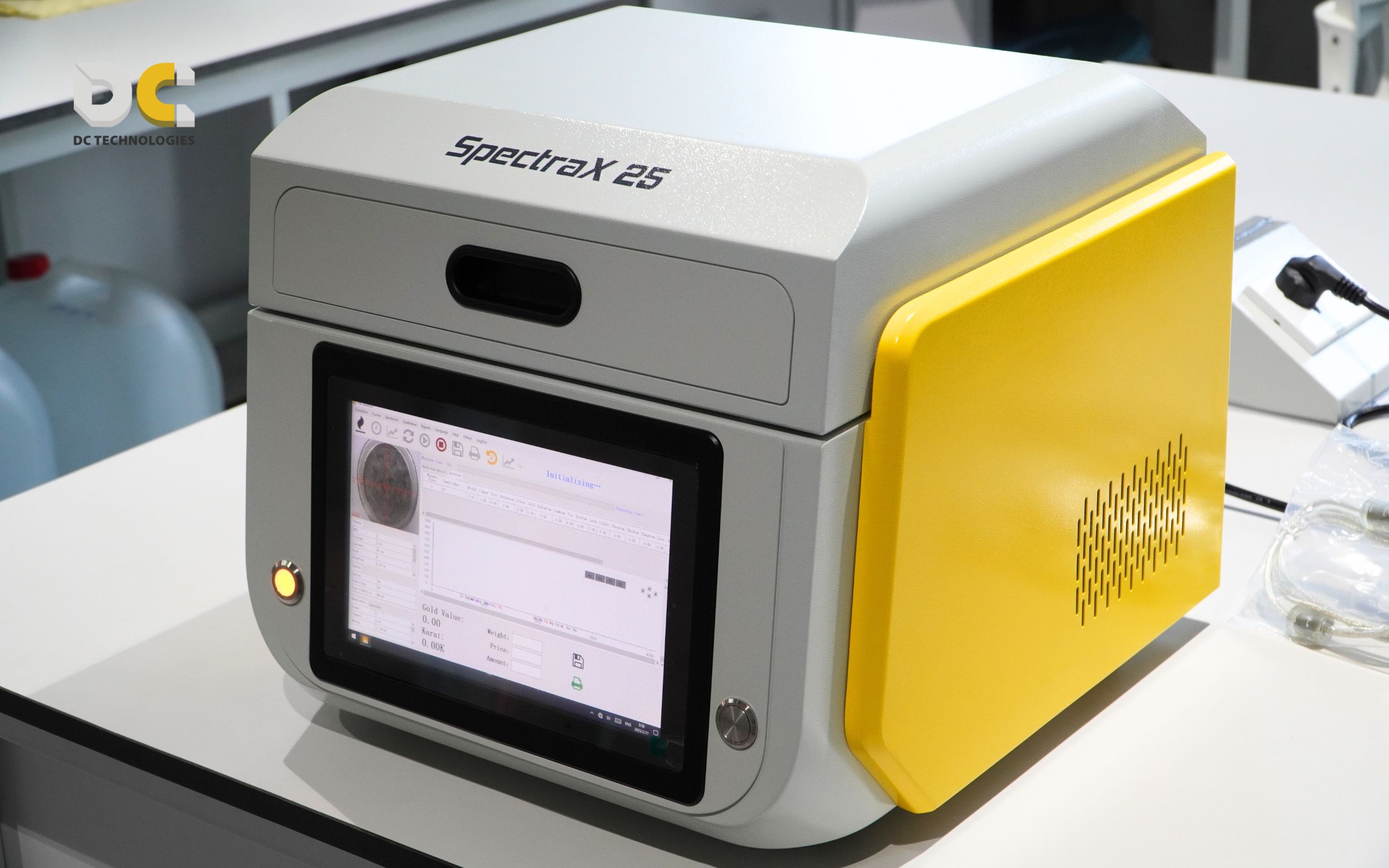

The SpectraX 25 is a next-generation benchtop metal analyzer and gold testing instrument that utilizes X-ray fluorescence (XRF) technology to determine the chemical composition and purity of metals. Widely used in the gold, silver, and jewelry industries, the SpectraX 25 not only enhances operational efficiency but also optimizes gold quality control processes.

Key Features of the SpectraX 25 Metal Analyzer:

- High-precision measurement: Provides accurate analysis of the elemental composition in metal samples without damaging or altering the physical state of the material.

- Advanced XRF spectroscopic analysis: Uses a non-destructive testing method that requires no complex sample preparation, ensuring reliability and ease of use in various testing environments.

- Sharp, user-friendly display: Equipped with a high-resolution LCD screen, the device allows users to easily monitor and interpret measurement results in real time.

- Instant results within seconds: Delivers rapid, reliable readings within just a few seconds, helping users save valuable time while maintaining consistent accuracy.

Figure 3: SpectraX 25 XRF metal analyzer

3. SpectraX 55 Metal Analyzer

Coating layers are widely used across numerous industries—from electronics and jewelry manufacturing to component production and consumer goods. To meet the growing demand for precision coating analysis, the SpectraX 55 was developed as an advanced solution for coating thickness measurement and metal composition analysis. Designed with state-of-the-art features, the SpectraX 55 not only measures coating thickness but also analyzes alloy composition, helping manufacturers enhance product quality and production efficiency.

Key Features of the SpectraX 55 Metal Analyzer

- Multi-layer coating thickness analysis: The SpectraX 55 can measure up to five coating layers, including the substrate, allowing users to analyze a wide variety of coated metal materials. Remarkably, it offers thickness measurement accuracy up to 0.001 μm—one of the highest precision levels available among XRF analyzers on the market.

- Alloy composition analysis of coatings: Accurately determines the elemental composition of coating alloys, including precious metals such as gold (Au), silver (Ag), palladium (Pd), platinum (Pt), and rhodium (Rh), as well as industrial metals like copper (Cu), nickel (Ni), zinc (Zn), and chromium (Cr).

- Toxic substance inspection under RoHS standards: In addition to coating thickness analysis, the SpectraX 55 supports toxic element testing in compliance with international regulations such as RoHS, WEEE/ELV, EN71, and TCVN. This is particularly crucial for industries like electronics and jewelry manufacturing, where environmental and safety compliance is strictly required especially for children’s products and consumer devices.

- Intelligent XYZ movement system: The 3D XYZ stage supports a maximum load of 5 kg, providing flexibility for analyzing large samples. A high-definition camera assists in precise measurement positioning, significantly improving the accuracy and repeatability of analytical results.

Figure 4: SpectraX 55 coating thickness analyzer

4. DXL 800 Gold Tester

Among today’s leading gold testing instruments, the DXL 800 from Thermo Fisher Scientific stands out as a top choice for jewelry stores, assay offices, and jewelry manufacturers seeking precision, speed, and reliability in metal analysis.

Key Features of the DXL 800 Gold Tester:

- Accurate precious metal composition analysis: Provides rapid and highly accurate quantification of precious metals such as Au, Ag, Pt, Pd, Rh, and Cu, ensuring reliable purity assessment for gold and other valuable materials.

- Ultra-fast measurement time (7–15 seconds/sample): Delivers instant analytical results in just a few seconds—ideal for jewelry shops or production facilities that require continuous and efficient testing.

- No sample preparation – non-destructive testing: Requires no cutting, polishing, or grinding. The device allows direct measurement on jewelry surfaces, coins, gold bars, or alloys without altering the product’s shape, integrity, or value.

- Compact, modern design for jewelry environments: Designed with elegance and practicality in mind, the DXL 800 fits seamlessly into showroom displays or in-store testing setups, making it a perfect choice for retail and professional use.

IV. Applications of Metal Analyzers in Jewelry Making and Manufacturing

1. Elemental Composition Analysis and Measurement

A metal analyzer helps determine the chemical composition of materials ranging from iron, copper, and aluminum to gold, silver, and platinum. In manufacturing and jewelry production, elemental analysis ensures:

- The mechanical strength and durability of components and parts.

- The purity and value of precious metals in the jewelry industry.

- Compliance with technical standards in metallurgy, precision engineering, and electronics.

With analysis speeds of just a few seconds, XRF analyzers allow businesses to control both incoming and outgoing materials without the need to send samples to a laboratory—saving time, cost, and reducing production risks.

2. Metal Recovery and Refining

Metal recovery and refining involve separati.ng valuable metals (such as Au, Ag, Pt, Pd, and Rh) from alloys or scrap materials. The metal analyzer acts as a digital assayer, determining the precise percentage of each element before extraction begins.

Using XRF technology in refining provides multiple advantages:

- Quickly assesses material value before refining;

- Optimizes precious metal recovery processes and minimizes material loss;

- Ensures transparency in pricing and trading of precious metal products.

3. Product Quality Inspection

Metal analyzers also play a vital role in quality control before products reach the market. The instrument verifies the grade of steel, alloy composition, or gold purity, ensuring every item meets technical and value standards.

Applications across industries include:

- Jewelry: Rapid testing of gold purity and karat value without damaging the item.

- Mechanical and metallurgical industries: Verification of alloy composition for compliance with engineering standards.

- Electronics and precision manufacturing: Monitoring heavy metal content in accordance with RoHS and REACH regulations.

V. Where to Buy Genuine Metal Analyzers

When choosing where to purchase a metal analyzer, it’s essential to consider several key factors to ensure both equipment quality and long-term reliability. DC Technologies proudly commits to providing customers in Vietnam with high-quality, advanced analytical instruments along with professional and dedicated after-sales service.

Figure 5: DC Technologies showroom space

Customers who purchase Thermo Scientific metal analyzers through DC Technologies will enjoy the following benefits:

1. Clear Origin and Authentic Documentation

Every analyzer must come with transparent paperwork and official import certification to avoid counterfeit or low-quality products. This is why many customers trust DC Technologies—we guarantee authentic products, verified origins, and international quality standards.

2. Comprehensive After-Sales Service and Warranty

A reliable instrument should be supported by professional post-purchase care, including 12–24 months of warranty, maintenance assistance, spare part replacement, and regular calibration services. At DC Technologies, customers are ensured fast warranty response and dedicated technical support whenever issues arise.

3. Technical Support and User Training

Not every user is experienced with analytical instruments from day one. That’s why a trusted supplier must provide on-site installation, user guidance, and technical training. DC Technologies prioritizes this commitment, helping customers gain confidence and proficiency during real-world operation.

4. Demo and Trial Support Before Purchase

It’s important to choose a supplier that offers demo sessions, trade-in and upgrade programs, and flexible pricing options tailored to different business sizes. Transparent and reasonable costs reflect professionalism and customer respect.

Figure 6: Trade-in and upgrade program

Currently, DC Technologies is offering a “Trade-In, Upgrade, and Save” program, allowing customers to upgrade their existing metal analyzers at a reasonable cost, access the latest technology, and significantly improve efficiency and analytical accuracy.

This is a valuable opportunity for businesses to enhance their inspection performance, ensure raw material quality, and achieve cost-effective, precise production control with confidence.

Conclusion

In the Industry 5.0 era, where material quality defines product excellence, investing in a metal analyzer is no longer a trend—it has become a core factor for businesses to maintain competitiveness and achieve sustainable growth.

From handheld models like the Niton XL2–100G to benchtop systems such as the SpectraX 25, SpectraX 55, and DXL 800, each device stands out for its measurement speed, precision, and versatility. These analyzers not only enable fast, non-destructive testing but also ensure accurate verification of precious metals, alloys, and coatings across diverse industries—from jewelry manufacturing and metallurgy to mechanical production and electronics.

Choosing a trusted supplier like DC Technologies ensures complete peace of mind regarding product quality, after-sales service, and technical support. More than a supplier, DC Technologies is a strategic partner that empowers businesses to advance their technology, optimize performance, and enhance production quality control.

Let DC Technologies be your reliable partner on the journey toward precision, innovation, and excellence in the new industrial era.

Website: https://dctech.com.vn/

Hotline: 0901 958 318

Showroom: 87 Nghia Thuc, An Dong Ward, Ho Chi Minh City

Head Office (HCM): High-Tech Center, 4th Floor, HUTECH Building, D1 Street, Saigon Hi-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City

Branch (Hanoi): No. 22B, O2 Linh Dam Peninsula, Hoang Liet Ward, Hanoi City

References:

https://dctech.com.vn/en/jmsblog-post?category_slug=chia_se_kinh_nghiem&post_id=697

https://dctech.com.vn/en/jmsblog-post?category_slug=chia_se_kinh_nghiem&post_id=689

https://dctech.com.vn/en/jmsblog-post?category_slug=chia_se_kinh_nghiem&post_id=690

https://dctech.com.vn/en/jmsblog-post?category_slug=chia_se_kinh_nghiem&post_id=685

https://dctech.com.vn/en/jmsblog-post?category_slug=chia_se_kinh_nghiem&post_id=678